Laempe Mössner Sinto GmbH will be showcasing its complete product and service portfolio at this year's GIFA (12 - 16.06.2023 in Düsseldorf) under the motto "the hybrid and digital core shop". The hybrid core shop enables foundries worldwide to achieve the necessary flexibility in an age of transformation - all with the aim of producing in a quality-oriented, resource-saving manner and at the lowest unit costs. In the hybrid approach, foundries and core manufacturers decide, depending on their individual product portfolio, which cores are produced traditionally ("shot"), which cores are produced via additive manufacturing ("printed") and which cores are possibly bought in ("core as a service"). The basis for these strategic decisions is provided by the reliable calculation data of our partner Tsetinis Software GmbH (TSET). Furthermore, empirical values and data in machine operation must be consolidated, visualised and evaluated. This real data provides information about the overall equipment effectiveness ("OEE") and shows improvement potentials for cost optimisation. With the "Laempe Digital Cockpit" (LDC), Laempe offers precisely this evidence-based decision-making basis for the operation of a core shop with its own software product. Laempe Mössner Sinto thus has the right solution for all the requirements of the modern foundry and will present its overall concept of the hybrid and digital core shop at its stand (Hall 17, Stand D23), including modern service concepts, and at the same time introduce its partners INACORE, TSET and pragmatric industries.

Foundries today face the challenge of managing a transformation process that requires new, and in some cases complex, geometries. At the same time, the focus is on marginal costs and the efficient operation of a core shop. Laempe Mössner Sinto already advises its customers on both issues and has the right solution for every challenge. "The purpose of the hybrid and digital core shop is to determine the optimal operating point so that production can take place at the lowest cost per core and with maximum resource efficiency. For this, foundries need the right equipment, the right know-how and intelligent software solutions for decision-making - we supply all of this," explains Andreas Mössner, Managing Director at Laempe Mössner Sinto.

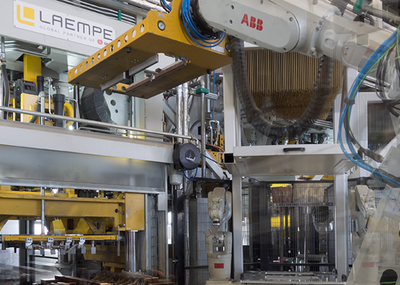

Laempe core shooters: from 1 to 1,700 litres shot volume

Laempe once started with the production of technologically leading core shooters and this expertise is still part of the core business today. At GIFA, Laempe will be showing a machine from the LL series and will also be presenting a shot core from the largest machine Laempe has ever built (type: LHL-200/1700).

LTF - the Laempe printer from its own development

Laempe has developed its own printer technology for sand cores in recent years. Laempe's 3D printing technology includes the printer (LTF), the microwave (LMW) the automation and the moulding material preparation and is perfectly designed for the needs of foundries due to its robust construction. In a few days' time, a first fully automated complete Laempe system will go into operation - this will also be on show at GIFA.

INACORE: Laempe partner for "Core as a service

Laempe offers its 3D printing technology not only as a complete solution, but also as a pay-per-part model via its partner company INACORE. The company in Ergoldsbach (Bavaria) has already been using Laempe printing technology for three years and has supplied numerous customers with printed cores during this time. Likewise, INACORE has been supplying its customers with shot cores since 2018, including BMW with its foundry site in Landshut, among others.

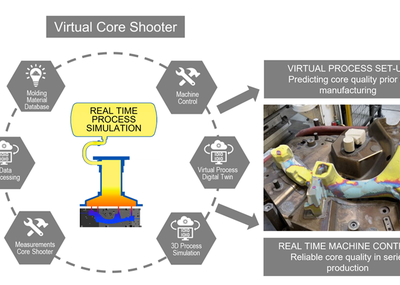

TSET platform: Laempe partner in calculating core costs

Today, very few foundries can reliably say how high the costs of a core are, taking into account the entire value chain. That is why Laempe has entered into a cooperation with the TSET platform. Based on the component geometry and the planned quantities, the platform can very quickly determine how much a core will cost and how much CO2 is likely to be emitted in the process.

LDC: The Laempe Digital Cockpit makes the efficiency of the plant visible

In cooperation with the start-up "pragmatic industries", Laempe has developed software that records and visualises the data in a core shop as the "Laempe Digital Cockpit". This makes it possible to determine, among other things, the overall equipment effectiveness (OEE) and also where the preventers of a top OEE lie: Is it downtime, is it scrap or is it the cycle rate? - The LDC provides answers to these and many other questions.

Laempe-AR: Help with problems in real time

Laempe has great know-how in the field of maintenance and repair of core shooters and plants. The company wants to make this know-how available to its customers, and for this purpose it has deployed the Laempe-AR system, developed by LaempeReich Co. This enables service technicians directly from Laempe locations to connect with customers worldwide and, with the help of a suitable device (e.g. VR goggles), to carry out troubleshooting together. This is a perfect solution, especially in view of the shortage of skilled workers, the limited availability of service technicians and process efficiency.

"We see ourselves as a companion to the foundries in their transformation. Here, partners are needed who are at the forefront of development and drive innovations that lead the entire industry to the desired goals of cost and process efficiency as well as resource conservation. Laempe is precisely this partner and we would like to demonstrate this with our presence at GIFA this year," explains Andreas Mössner.

About Laempe Mössner Sinto GmbH

Laempe Mössner Sinto GmbH is the world market leader for core shooters in the foundry industry and covers all areas of modern core production with its comprehensive product and service portfolio. The traditional German company is a complete solution developer with its headquarters in Barleben/Meitzendorf in Saxony-Anhalt. A total of 380 people are employed at this state-of-the-art production site, at the branches in Schopfheim in the Black Forest and Mannheim, and at the subsidiaries in Pune (India) and Beijing (China). www.laempe.com