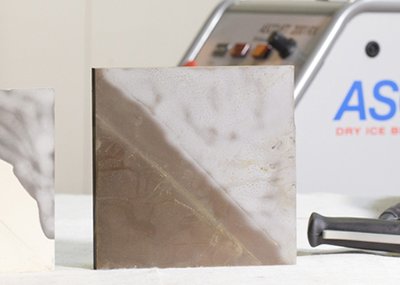

ASCO CARBON DIOXIDE LTD presented its expanded range of ASCOJET dry ice blasting units and thus the new ASCOJET Combi blaster 1708 for the very first time ever at GIFA 2015, 16 to 20 June in Düsseldorf, Germany. The recent machine is equipped with a new developed dosing device which allows the use of an additional blasting material in the dry ice stream. Thanks to this system, customers receive the best combination of gentle cleaning with dry ice pellets and the additional abrasive effect of a carefully selected additive.

Besides the fact of a highly efficient blasting result due to combining dry ice pellets and additive, the new ASCOJET Combi blaster 1708 persuades its future owners with additional benefits such as a reduced noise emission thanks to lower air consumption, a minimum secondary pollution and an easy operation.

By taking a close look at the exhibits, the visitors were able to convince themselves of the capabilities of the entire product range of ASCOJET dry ice blasting units personally at the ASCO booth. Roberto Sammali, Sales Director Dry Ice Blasting at ASCO, comments on the trade fair as follows: "We are very satisfied with the event's results and the overall positive customer feedback. The high number of attendees confirmed the brisk interest in mould cleaning with dry ice. Furthermore, ASCO´s commitment to dry ice technologies and the introduction of the new ASCOJET Combi blaster 1708 are further important steps forward to complete our market offer, especially in reference to optimal cleaning results of moulds and core boxes in foundries.“

However, ASCO´s solutions not only include intensive advice in choosing the right dry ice unit. Rather it`s all about providing dry ice at the right time, the right place and above all in excellent quality to achieve optimum cleaning performances.

Sammali adds: "In these five days of exhibition we were able to present our individual overall solutions to many customers and prospects in face-to-face consultations. For this reason, we would like to say thank you for the many useful discussions and the exchange of experiences."

Partner

Foundry Corporate News

Topic Discharging, Decoring, Fettling, Finishing

Topic Plant Technology, Equipment

Topic Pressure Die Casting

Topic Machine mould casting

GIFA 2019

ASCOJET dry ice blasting technology attracted the crowd at GIFA 2015

Reading time: min

[3]