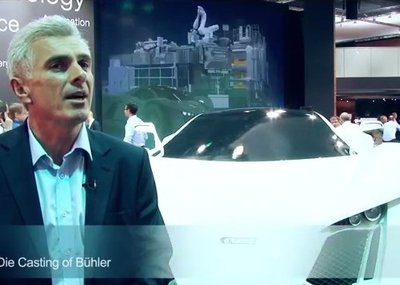

Bühler will be taking part in celebrating the anniversary of EUROGUSS in Nuremberg. Bühler will show its innovative top products and high-quality services at the 10th International Trade Fair for Die Casting. Jonathan Abbis, the new manager of the Die Casting division will also be there and is looking forward to his initial conversations with customers.

As a globally leading technology partner in the die casting industry, Bühler sets standards in the area of productivity, energy efficiency and customized solutions for producing structural components. As the international die casting industry meets for the tenth time in Nuremberg from January 14 to 16, Bühler will be highlighting an innovative range of products and services including Carat, Ecoline Pro, Lost Core and Structural designed to meet the highest demands and looks forward to welcoming and talking to many customers and visitors. Jonathan Abbis, the new manager of the Die Casting division plans to take advantage of this excellent and well-established platform provided by EUROGUSS to meet customers and conduct initial talks with them. A record number of participants is expected this year at EUROGUSS. Highlights of the fair from the last ten years, a special show and lectures on the latest research and practices will all be part of Europe’s most popular trade fair.

Services – Modular and Individual

For all innovative advancements in the industry, economic effectiveness is of vital concern and demands continuous optimization of productivity and availability of production facilities. Die casters can only gain an advantage and work successfully if they have a stable manufacturing process and finely tuned procedures. That is why Bühler not only supports its customers with state-of-the-art production technology but also provides valuable consulting services worldwide to ensure sustainable and trouble-free operation of manufacturing plants.

Top Notch thanks to Carat

High productivity and precise applications – these are the performance features of the Bühler

Carat. The real-time-controlled dual-plate die casting machine produces parts that are optimally suited to a particular application, making Carat the ideal solution for customers who manufacture complex parts and have high expectations of quality.

Ecoline Pro – Maximum Productivity and a High Degree of Flexibility

Ecoline Pro is the ideal Bühler alternative for die casters who rely on proven high-performance die casting technology. The cold-chamber die casting machine focuses on the essentials: ease of operation, maximum uptime and flexibility. The well-designed construction guarantees maximum productivity and is impressive in its robustness and reliability. Ecoline Pro is perfectlysuited to meet the challenges of changing production and also consistently lowers the costs of service and spare parts.

Structural and Lost Core – State-of-the-Art Technologies

Optimized processes lead to better results. With the Structural process, Bühler guarantees cost-efficient production of structural components with aluminum die casting, an area that has gained in importance for the automobile industry in particular. Light construction is an essential criterion for reducing CO2 emissions. Tests have proven that lowering the weight of a vehicle by 100 kg will result in a reduction of 8.5 grams of CO2 per kilometer driven.

Such trends towards energy savings and the ever increasing pressure on costs require continuous innovation. Bühler’s Lost Core technology also creates great potential and combines the advantages of die casting with the numerous possibilities for design typically common in gravity and sand casting.

Die Casting under New Management

Jonathan Abbis has taken over the leadership of the Die Casting division, a business unit that holds its own in a highly innovative market. The British-born Abbis officially assumes his new managerial role on February 1, 2014. “The Die Casting business unit is well-positioned and successful – so I will mainly be continuing the work of my predecessor, Dr. Bernhard Fritsche”, explained Abbis who will conduct his first customer talks at the EUROGUSS 2014. “It is important to me to be in continuous dialog with our customers. That is how we can determine where and how our work can be optimized.”

Jonathan Abbis studied mechanical engineering at the renowned Stanford University in California. In 2010, he took over the management of the Aeroglide business unit that is part of Bühler’s Food Processing division. Jonathan Abbis was responsible for Aeroglide’s successful integration into the Bühler Group and guided this market leader for industrial dryers to profitable growth.

Please visit Bühler at the EUROGUSS 2014 – from January 14 to 16 – in hall 7, booth 7-216. On opening day, we will have a booth party with musical entertainment starting at 5:00 p.m. We look forward to seeing you there!

Partner

Foundry Corporate News

SPECIAL - Pressure diecasting

Topic Pressure Die Casting

Bühler to Show its Top Products at the EUROGUSS Trade Fair

Reading time: min

[0]