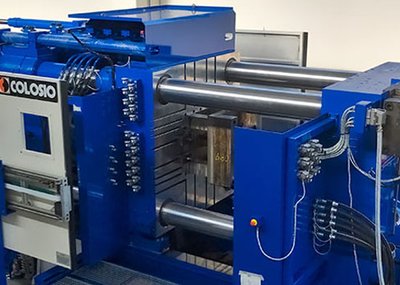

UK-based Clamcleats Ltd have recently purchased a new, cold chamber die casting machine, made by Colosio Srl, to help revamp their existing foundry in Welwyn Garden City. Clamcleats Ltd have been manufacturing in the UK since their formation in 1965, and are investing to ensure that their UK manufacturing continues to grow.

This cold chamber die casting machine comes equipped with a data storage system, allowing accurate repetition of all injection parameters, keeping all moulds consistent, allowing improved quality.

A new furnace will be the first piece of equipment to be installed, arriving in June 2016, with the die-casting machine arriving in the first week of July 2016, keeping the products competitive for future markets.

Benefits of the new die casting machine

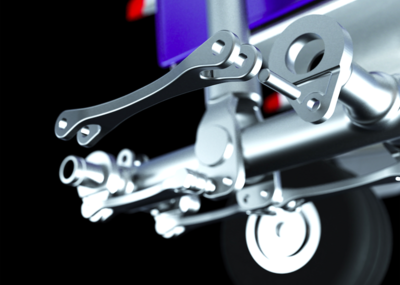

The machine will come supplied with a robotic die sprayer and ladler for pouring the molten aluminium, this will allow a fully automated cycle where appropriate.

Continuous cycling will bring a consistency to the process leading to an increase in capacity and shortening of lead times.

The increased capacity allows flexibility for Clamcleats Ltd to offer support to outside customers regarding custom projects. The machine is able to produce a locking force of 200 tons, and can cast up to 2.7kg per shot.

The machine has been ordered in the Green Line version, lowering noise levels, reducing the need for cooling fluid and reducing energy consumption by up to 80%!

With the entire foundry undergoing a refurbishment, it has taken careful planning to avoid disruption to the market.

Partner

Foundry Corporate News

Topic Pressure Die Casting

COLOSIO - Clamcleats Ltd have purchased a new Die Casting Machine

Reading time: min

[5]