MAGMA presenting the latest advancements in casting process optimization software

For the 13th out of 13 times, MAGMA is taking part in the Asian Foundry Congress (AFC) taking place in Hanoi – Vietnam from 27th – 29th October 2015. MAGMA Engineering Asia-Pacific Pte Ltd – Singapore is represented by Mr. Christian Kleeberg, the Group Managing Director of MAGMA Asia group of companies. This year MAGMA is going to introduce 2 brand new technical papers: “Gating system optimization using virtual experiments” and “Advancements in Core shooting simulation”.

“The AFC has become a part of tradition for MAGMA in Asia, and we at MAGMA fully support the aim of the Asian Foundry Congress to strengthen the communication and cooperation among Asian foundry industries, seeking common development, and enhancing the cooperation among different countries, regions and members” says Mr. Kleeberg. “In the global world we live in, it is not enough to accept the status quo. We need to accept and even embrace change, be it in regards to safety aspects, environmental ethics or like in our case – implementing a revolutionary new integrated methodology approach as is casting process optimization with MAGMA5 Rel.5.3. It is MAGMAs goal to partner with the foundry industry and educate the market about new technologies to get a competitive advantage and being able to produce quality products as cost efficiently as possible by reducing trial and error with virtual optimization.”

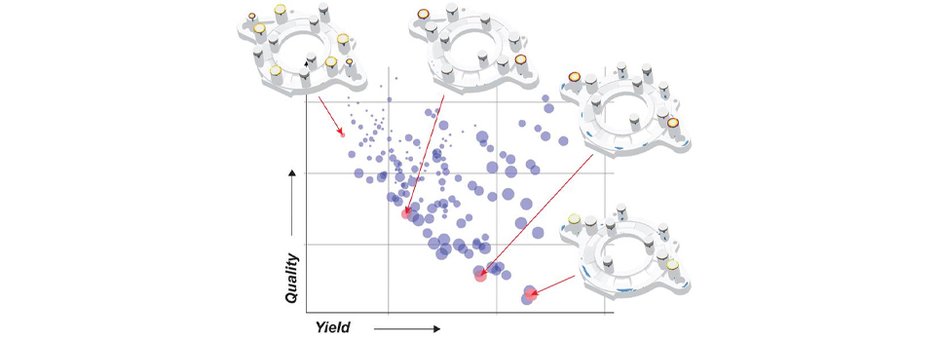

For the first time and with the introduction of the latest release of the software MAGMA5 Rel.5.3 we offer our customers the potential to fully optimize casting designs, methodologies, processes and related costs all in one software. The optimization approach gives us the opportunity to explore and test multiple theories and approaches at the same time and returns quantitative results, so we can make educated decisions for example on which gating system to choose, or which is the best pouring temperature.

In simple terms MAGMA is now able to quantify any quality criterion and the application is moving away from subjective interpretation of simulation results to an objective assessments of all results achieved providing ultimately the compromise solution.

Partner

Topic Simulation

Foundry Corporate News

MAGMA at Asian Foundry Congress in Hanoi / Vietnam 2015

Reading time: min

[1]