Pyrotek develops innovative systems for all foundry processes, which promote uniform and controlled heating, reduce energy costs, extend refractory life, improve metal quality and increase metal recovery.

Pyrotek will exhibit at GIFA, an international foundry trade fair and technical forum, 16–20 June 2015, in Düsseldorf, Germany.

During the 5-day event, Pyrotek will highlight its innovative foundry solutions, which improve metal quality and promote energy savings, efficiency and safety. The emphasis will be on how these benefits are demonstrated in a broad range of products for all foundry processes, including scrap preparation and remelting, metal treatment, metal transfer, metal holding, low-pressure diecasting, high-pressure diecasting and gravity casting.

Pyrotek’s foundry products and equipment offer many energy-saving features: uniform and controlled heating, increased refractory service life, reduce energy costs and improved metal yield and recovery. Additionally, Pyrotek’s global presence makes it uniquely positioned to offer comprehensive solutions backed by engineering expertise and local support. Pyrotek’s team of furnace specialists and engineers will be at GIFA to discuss the complete refractory relining services for a variety of holding furnace designs.

Visit hall 11, stand A22 to see an immersion heater furnace refractory liner, an innovative heated launder system and Pyrotek’s new RFM® Overflow Pump, which is designed to transfer molten metal from small crucibles or melting and holding furnaces.

Our sales engineers will be in hand to answer your questions and there will be refreshments and snacks available, as well as promotional giveaways like chocolate covered coffee beans, cell phone power banks, and spiral bound notebooks.

The following Photos courtesy of Pyrotek Inc.

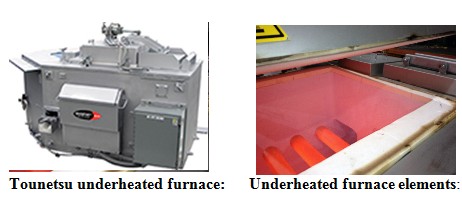

Tounetsu Furnace - Refractory Liner

Pyrotek’s team of furnace specialists perform complete refractory relining for a variety of holding furnace designs. Relining technologies include precast shapes and in-situ casting.

Benefits:

- Uniform temperature maintained in the melt

- Less energy consumption

- Less oxide formation extends furnace life

- More durable material, fewer repairs

RFM (Reinforced Refractory Material) Overflow Pump

The new RFM® Overflow Pump is designed to gently raise and transfer molten metal from small crucibles or melting/holding furnaces. Its efficient pumping design can quickly empty a small crucible in minutes.

Benefits:

- Improved operational safety

- Easy to handle (hot or cold)

- Quick submergence

- Compact and reusable design

- Shaft/impeller easy to exchange

Photo RFM Overflow Pump:

Heated Refractory Launder Technology

Pyrotek's heated refractory technology continuously heats the refractory launder using an innovative heating panel system. The design reduces furnace energy costs and increases the service life of the launder refractory when compared to traditional launder heating systems.

Benefits:

- Uniform and controlled heating

- Reduced energy costs

- Increased refractory service Life

- Low maintenance—reduction in joint and coating maintenance

Heated Refractory Launder System