Since the introduction of SEDEX Iron filters more than 25 years ago, there have been many advances in terms of product performance and application technology. Today Iron filtration is regarded by most foundries as standard practice – the value and benefits of effective ceramic foam filtration are well documented and understood.

FOSECO has continued to work with customers to develop SEDEX application technology to meet the increasing demands of casting end users. Gating system design can now be accurately modelled using MAGMASOFT casting process simulation software, and greater consideration is now given to the fluid flow characteristics of the melt.

A series of Iron and Steel case studies will be used to demonstrate the latest advances in gating system design for both horizontal and vertical parted moulding. Both conventional gating systems and KALPUR direct pouring systems will be highlighted.

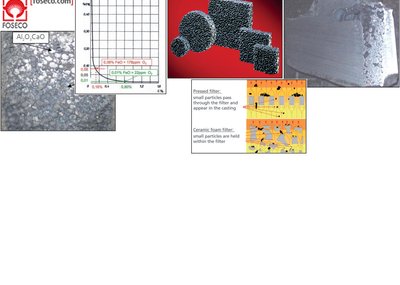

SEDEX filters today provide the most consistent metal flow rates and capacities for the customer, delivering the highest levels of filtration efficiency and inclusion removal.

Steel filtration technology has also advanced significantly in the last few years and foundries are now applying filters to castings of over 50 Tonnes cast weight using the HOLLOTEX CFU7 system.

FOSECO will be introducing new technology associated with our STELEX Filter offering. This will provide improved consistency of performance and allow the application of finer porosity filters where not previously possible. The steel foundry using the STELEX filters will enjoy the benefits of enhanced filtration efficiency and flow control resulting in their ability to produce higher quality and cleaner castings

Partner

Foundry Corporate News

Filtration Technology for Iron and Steel Foundries

Reading time: min

[21]