Digitalization and sustainability are the major topics in the iron and steel industry - and for ABP Induction. This is not surprising, after all, the steel industry is considered to be responsible for around nine percent of current global CO2 emissions. Thus, almost every technical discussion in steel mill technology addresses the switch to sustainable and long-term climate-neutral production technologies. With the CO2-neutral induction technology for heating and melting, ABP Induction provides an optimal solution for this.

„With ABP Induction‘s products, we have gained a significant complementary technology in our portfolio,“ Stefan Fellner, Vice President Plant Solutions at ABP‘s parent company Primetals Technologies, also confirms. „The integration gives us the opportunity to offer our customers high-quality technical solutions with induction melting and heating technologies from a single source.“

Due to the high importance of this market, ABP has bundled global sales and product responsibility: Achim Thus, in addition to his role as product manager for heating technologies, represents steel mill technologies on a higher level. Markus Hagedorn supports him as product manager for the optimized IFM-S melting furnaces. They are supported by the global ABP network with nine subsidiaries and local business partners. In addition, ABP Induction will continue to be present globally at the most important events in the industry, most recently at AISTech or ESTAD in Sweden with a joint presentation by Primetals and ABP. The current trade fair dates can be found at www.abpinduction.com

ABP‘s products are technically optimized with a focus on the needs of modern high-performance steel mills:

- Heating: High-precision control of heating for flat material and long products, among other things as core equipment in the Endless Strip Production (ESP) of Primetals or in the long product area in the current project with partner Steeltec.

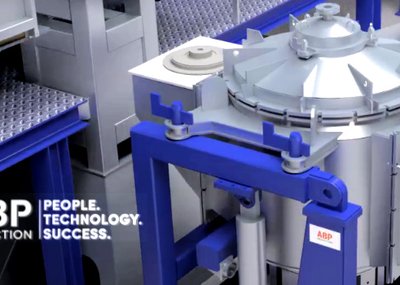

- Melting: The proven IFM-S crucible furnace with melting capacities of up to approx. 900,000 tons per year offers the highest possible productivity, energy efficiency and automation.