FLOW-3D® renowned for the accuracy and versatility for the simulation of casting processes has been supplied with additional physical models in its version 10.

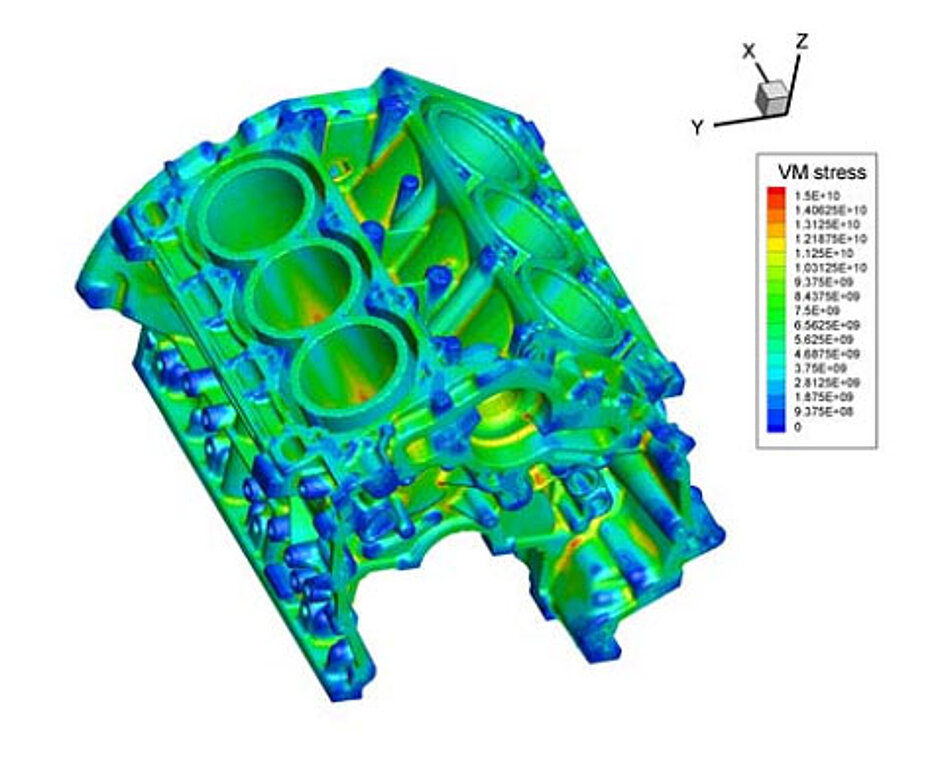

Thermal stress evolution model

The thermal stress evolution model describes the evolution of stresses and deformations in metal during cooling using a finite element approach. Stresses are simultaneously computed in the mold and in solidifying metal with different options for the interaction between them.

Core drying model

The use of water based binder systems for the production of sand cores is becoming increasingly popular. This model uses a two-phase liquid/gas model allowing for evaporation and condensation for the accurate prediction of the core drying process. The picture shows remaining areas of wet sand.

Cast iron solidification model

The cast iron solidification model describes eutectic and near-eutectic solidification of cast irons, coupled with the solidification shrinkage model. The formation of austenite, graphite and carbide phases is also predicted.

###COMPANY_LINK### <link record:tx_browserdirectory_directory:4896 internal-link>![]() Flow Science Inc.

Flow Science Inc.