After the shutdown of public life and large parts of industry in Germany and Europe, it was high time for the Foundry-Planet editorial team for the first factory visit after the crisis.

The European Union has just decided to support the ailing economies with record sums in the European Economic Area.

In China, but also in Europe, there are clear signs that the 3rd quarter of 2020 could pick up strongly, so good signs for looking ahead.

We visited the Swabian mold and tool maker Schaufler Tooling GmbH & Co.KG in Laichingen and had the pleasure to meet Mr. Siegfried Heinrich and Mr. Marc Klapper and thank you for an interesting conversation.

The effects of the pandemic changed a lot overnight, including at our offices in the US and China

After the first months of the pandemic experience and its effects, the managers at Schaufler Tooling GmbH & Co.KG were confronted with completely new challenges almost overnight, reports CEO Siegfried Heinrich, after OEMs and die casting were largely at a standstill worldwide. In Germany, we were able to adapt the short-time work regulation very quickly and quickly apply for KfW loans, so that current orders could be served well and we are financially prepared for all eventualities, reports Heinrich.

The situation is different at Fischer Tool & Die, the US subsidiary of the SF Tooling Group, where the workforce initially had so-called temporary leaves and, from the end of April, liquidity was secured with state-covered loans. In Schaufler China Co., Ltd., where Schaufler Tooling cooperates with two well-known, strategically Chinese mold making companies, the partners were able to cushion the challenges comparatively well. In general, business in China is developing very well despite the Covid-19 pandemic and mold construction there is in no way inferior to European standards in mold production.

There, too, 5-axis technology and high-speed machines are used to manufacture molds for complex cast parts, but in the high-end segment the know-how, simulation, design, thermal household calculation and engineering still come from Germany. In the medium term, people are also thinking of having their own assembly site in China.

"Let's look ahead and check the Corona year"

“In 2019, the trade magazine Wirtschaftswoche counted the SF Tooling Group with Schaufler Tooling in Germany and Fischer Tool & Die in the USA among the world market leaders. "I cannot predict whether we will be able to achieve that in terms of sales this year, I think we should check the corona year and look ahead."

Siegfried Heinrich does not allow any uncertainty at all, because he is convinced that his company will cope with the challenges and is well positioned, because the corona effects are temporary.

The entrepreneur sees the situation very realistically and expects good opportunities for Europe shortly, because the average age of the vehicles is relatively high and that means replacement needs and fleet renewal is imminent. The export of vehicles could become less in the medium term because the value chains tend to shift to other markets in the direction of Asia.

The investment climate for OEMs and suppliers in the automotive industry is determined by the transformation and the discussion about alternative drives, connectivity and autonomous driving, so that classic investments are sometimes delayed. Overall, it can be seen that the variety of models is being reduced in favor of future technologies.

However, anyone who claims to know how the transformation of the drives is really developing must be a clairvoyant, because we are in very young and dynamic technologies that make forecasting difficult. In any case, there are excellent opportunities for die casting in the light metal sector for each of the possible drive types to be part of the demand and supply chain, and that for all common drive types in parallel for the coming years. This requires a high degree of flexibility and knowledge transfer and challenges everyone involved to work more closely together. In Heinrich's opinion, mold makers and foundries could well be involved in the development processes earlier.

Everything that makes die casting more competitive overall is also good for mold making, including integrated large cast parts for the body

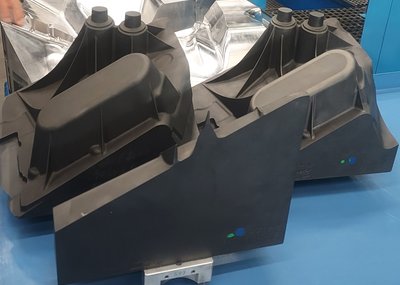

Of course, die casting is extremely dependent on the automobile and the question of how much die casting is left in a purely electric vehicle has not yet been decided. It is not necessarily European manufacturers who set the pace. Siegfried Heinrich is convinced that all OEMs are closely following Tesla's bold plans to use large-scale, highly integrated cast parts for body-in-white construction and drawing their conclusions. When asked to what extent mold making is already prepared for these challenges, he is diplomatic. This is a new league of tools that did not exist up to now, so it is necessary to build up the appropriate infrastructure in order to be optimally set up, but that is possible and feasible.

In general, Heinrich advocates that the industry and those involved in the process use all technological advantages. As usual, the die casting mold is about the potential for improvement in terms of quality, service life and cycle times.

Whether there are alternative, new areas of application for die-casting, Heinrich mentions the electronics, photovoltaics and mobile phone technology environment, especially when it comes to the need for 5G expansion, there are interesting examples of die-cast housing technology.

With ambition and optimism into the second half of 2020

The signs of an economic recovery are palpable, governments around the world are campaigning for rapid and sustainable industrial funding and, as is so often the case, psychology plays a decisive role in the current situation. Siegfried Heinrich exudes confidence, when asked about the outlook for the second half of 2020, he is confident. “We still have big plans for 2020, the order books are full and we have new projects. There are so many interesting and forward-looking aspects that affect die casting and mold making and good work is being done everywhere.

In addition to the technology for new large cast parts, we see great challenges and optimization opportunities on many levels. The consequences of the pandemic may contribute to global standardization becoming more important. With standardized machine interfaces, you could save expenses and unnecessary costs, drive the trend towards standard parts and, in the Internet of Things (IoT), please do not neglect mold making. This is a plea for closer cooperation between manufacturers, foundries and mold making and an optimistic signal for the entire industry.

Thank you for the interview - Good luck to Schaufler Tooling GmbH & Co.KG!