PS Auto Grinding Now Have Over 250 Installations in Europe Alone

There can only be two ways to ensure a foundries survival and success moving forward.

- Sell More

- Reduce Operating Expenses and Risk of Variable Costs Rising

With some notable exceptions in the foundry trade, selling more castings in Europe is proving a difficult task.

Clearly, labour is the most controllable factor a Foundry Manager has at his/her disposal and the largest percentage of labour is in the grinding department, often around 25% of total employees and recognised estimates say that the fettling shop accounts for 10-15% of total running costs. It is also a fact that energy and material costs are difficult to control dramatically to make a major impact on cost.

Many foundries, large, medium and small still accept it is standard and acceptable business practise to find cash every month to pay a large team of hand grinders and the team of inspectors, trainers, supervisors that supports them.

This labour can be controlled by introducing PS Auto Grinding Machines and foundries in 16 countries throughout Europe have recognised this and acted by installing PS Auto Grinding Series 400 & 500.

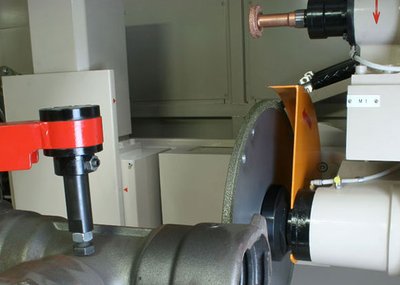

3, 4 or 5 times as fast as a hand grinders, the machines are accurate to 0.1mm every casting and being enclosed are much safer than open hand grinding for the foundry worker.

It is not uncommon for foundries to have 100 grinders at benches over 2 or 3 shifts plus another 10-15 support workers.

Typical Grinder in Foundry: Slow, Dusty, Heavy and Dangerous Work

Many foundries outsource this activity to Grinding Shop specialists and this attracts a premium over in- house grinding and also requires cash to be available and paid monthly. Recently one 400 tonne per month foundry producing 5-10KG grey iron castings told PS Auto Grinding they pay over €40,000 per month for grinding!!

PS Auto Grinding Limited’s range of Market Leading Automatic Grinding Machines reduces labour requirements by, usually 60%+ and total costs by about 50%.

With fully loaded salaries in Europe and rising wages in Central Europe, Turkey and Russia the payback on machines can be from as little as 1 Year!

Example Payback Calculation (based on German Foundry Trial with 5 Castings)

| Number of shifts / day | 3 | ||

| Manpower cost including social costs per annum | €25000 | Fully Loaded Cost is Recognised as Higher in Western Europe | |

| Manpower saving allowing for 1 machine operator / shift | 4.25 | Machine Trials 5.25 faster than manual grinding | |

| Machine Cost | €350000 | ||

| Cost of consumables per annum | €2400 | Based on 1000 hours wheel life | |

| Payback time (years) | 1.11 |

With an expected life of over 15 years PS Auto Grinding Machines must be amongst the best investments in the foundry trade that can make almost an immediate impact on productivity, profitability, quality and safety.

Many foundries are calculating that even with buying the machine on finance or leasing, and the addition of interest charges, the payback is so fast that it makes no sense to delay this ‘labour saving process’ along with other immediate benefits, most notably quality of grinding improvements. In fact the savings in cash required for wages can help fund other capital investment improvements to the foundry.

| Like us on | <link http: www.facebook.com pages ps-auto-grinding-limited _blank external-link-new-window external link in new> |

###COMPANY_LINK###<link linktosingle> P.S. Auto Grinding Ltd.