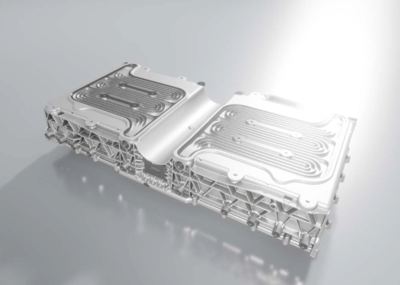

GF Casting Solutions builds upon its expertise in bionic design to achieve even more weight reduction for its cast components. For commercial vehicles, this is a real challenge especially because of the tremendous forces that are exerted on the components. GF's bionic wheel hub shows that it is still possible to reduce weight by 13%.

"With bionic design, we have found a way how we can design sophisticated structures which are thin-walled but still stiff and durable." -Dominik Mahnig

As the wheel hub connects the rim and the axle of the vehicle, it is heavily stressed by vertical, lateral and braking forces. For many manufacturers, this is the reason why it is made of cast iron. GF Casting Solutions has developed a wheel hub for commercial vehicles made of ductile iron and, inspired by nature, featured it by special gaps and ribs which makes the new wheel hub much lighter than its predecessor. Its weight could be reduced by 4.8kg to a total weight of 33.3kg.

In addition to weight reduction – amounting to as much as 50 kilograms per truck – the bionic wheel hub offers another advantage. The gaps and channels improve air circulation, which supports brake cooling.

Thanks to computer programs, Dominik Mahnig’s team could calculate where less material could be used without impacting stability. In multiple iterative rounds, the wheel hub arrived at a shape with organic-style holes, gaps and ribs. An enormous advantage is not only the weight reduction but the accompanying cost reductions due to a lower fuel consumption and a higher payload of the vehicle.