<link http: www.foundry-planet.com _top external-link-new-window>KMA ULTRAVENT is the world´s most sold waste air filter system for die casting machines. It covers a comprehensive range of smoke extraction hoods and heavy duty smoke filter systems in accordance with ISO 14000 standards.

Workers in traditional die casting foundries are often exposed to high concentrated oil fumes and mist, caused by mold and piston lubrication systems. Today regulations for occupational health and workers security demand for effective smoke and mist removal in die casting foundries. <link http: www.foundry-planet.com _top external-link-new-window>KMA, a german specialist for air filtration in die casting foundries, has created a wide range of high efficient smoke extraction and filter systems, which became well known under its brand ULTRAVENT.  High efficient fume extraction for clean air in the foundry: The fume extraction hoods are placed on top of the diecasting machines in order to catch all fumes from the mold and the piston area. The extraction hood is usually linked to a fume filter, consisting of demisters and electrofilters for high efficient filtration of smoke. The clean air flows back into the die casting shop, hence no tubework to outside is required. In case of change of molds, the fume extraction hood can be removed from the die area within a few seconds by shifting the hood elements like a telescope over the smoke filter. By this way an easy and unrestricted crane access to the molds is provided.

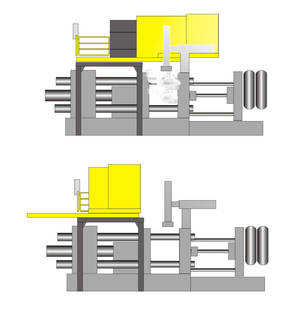

High efficient fume extraction for clean air in the foundry: The fume extraction hoods are placed on top of the diecasting machines in order to catch all fumes from the mold and the piston area. The extraction hood is usually linked to a fume filter, consisting of demisters and electrofilters for high efficient filtration of smoke. The clean air flows back into the die casting shop, hence no tubework to outside is required. In case of change of molds, the fume extraction hood can be removed from the die area within a few seconds by shifting the hood elements like a telescope over the smoke filter. By this way an easy and unrestricted crane access to the molds is provided.

Automatic filter cleaning: Oil mist in foundries causes lots of dirt on the filter surface. At ULTRAVENT, all filter elements are washable. Hence no change of filters is required. Due to the automatic filter cleaning system (cip) which is part of the ULTRAVENT filter, frequent washing runs automatically.

Siemens PLC control for:

<link http: www.foundry-planet.com _top external-link-new-window>KMA´s plc-control is based on Siemens S7-312 and runs with the new software UV-PRO-LOGIC. It provides an advanced filter control and meets all requirements for ISO 14000 certified companies.

For more information visit KMA at Ankiros or at <link http: www.ultravent.com _blank external-link-new-window>www.ultravent.com

KMA ULTRAVENT telescope hoods |  Scheme of a KMA ULTRAVENT filter system above a DCM |

<link http: www.foundry-planet.com _top external-link-new-window>Click here for more Information and Contact to KMA Umwelttechnik GmbH in our Suppliers Profile