|

also available in <link _top>![]()

Over 200 successfully implemented systems bear witness to their in-depth expertise. These include not only robot cells but also turnkey systems developed by KOCH as the main contractor. One of the leading suppliers in its field, the highly specialised robot systems company saw its triple anniversary at the end of 2008 as an ideal opportunity to invite customers and guests from industry and the various trades to their in-house fair featuring a large robot show. One of the real crowd-pullers was the KUKA titan boasting a load-carrying capacity of 1,000 kilogrammes, the world's strongest robot according to the "Guinness Book of Records".

But the numerous visitors were also thrilled by the other, job-specific KOCH systems and the host of many other KUKA robots. In addition to full details about the in-house fair you will of course also find on the website robotersysteme.com comprehensive information on the entire KOCH portfolio.

Custom-designed complete solutions

KOCH's expertise is revealed too in the modern primary control systems the company can optionally link to superordinate systems such as PPS and SAP. What's more, by using standardised software modules in robot and system control units KOCH also guarantees optimised ease of operation coupled with swift and economical implementation of the systems.

The core skills of the specialist firm for high-availability complete systems, which was one of the first to be accepted into the small circle of official, certified KUKA system partners, also include developing application-specific robot grippers.

Future-proof engineering guaranteed

In today's fast-moving times the only thing we can be sure of is change. KOCH addresses this reality with maximum system flexibility. The robot systems company can therefore guarantee high adaptability to new products and applications, and thus future-proof engineering. But the arguments the users immediately benefit from are equally compelling, including substantial reductions in costs, which can mainly be seen in multiple-shift operation, high production reliability thanks to system availability which is always in excess of 95 per cent, coupled with improvements in quality as the result of minimising mistakes and friendlier workplaces.

„Examples for handling and machinery interlinking using KOCH robot systems"

|

|

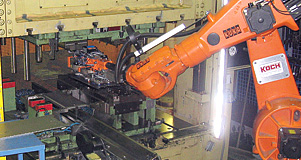

KUKA heavy-duty robot KR 1000 titan | Feeding a two-stage press. |

|

|

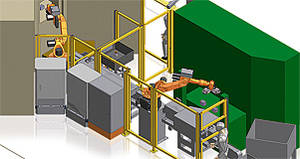

Automatic interlinking of a machining centre with | Machine interlinking for car brake parts |

Contact to <link _top>KOCH Industrieanlagen GmbH in our Suppliers Profile