"The research leading to these results has received funding from the European Union's Seventh Framework Programme managed by REA-Research Executive Agency <link http: ec.europa.eu research rea _blank external-link-new-window external link in new>![]()

Partners

The project comprises 7 partners from 4 European countries, 4 are SME (57% of the consortium) and 3 are RTD.

| Partners | Main roles within the project |

Project Coordination |

|

|

|

|

|

| |

|

|

|

|

|

|

Outline

- In spite of the advantages of using aluminium light-alloys in applications requiring weight reduction, its use is limited by the quality and insufficient properties of the cast parts that suffer from gas porosity due to the presence of hydrogen in the molten metal. A clear example of this can be seen in the automotive sector (newly developed electric and hybrid vehicles).

- The current degassing techniques, based on the purge of a gas mixture through the melt have been proved to be expensive and harmful to one’s health (often containing chlorine or fluoride) and have shown limited efficiency.

Ultragassing project targets at applying an ultrasonic degassing treatment on light-alloys, enhancing significantly the value of the cast parts produced by the EU foundries in terms of safety and quality. - The application of the developed within this project technology will allow the participating SMEs to solve at least two problems: (1) eliminate non safety and health hazardous technologies currently used and (2) improve degassing efficiency.

- Prototypes from the developed technology will be constructed and validated on 3 different industrial casting technologies (High Pressure Die Casting with vacuum; Low Pressure Die Casting; and Gravity Casting).

- The Ultragassing Project is an example of R&D project that will suppose an important improvement for the EU foundry sector of non-ferrous alloys.

- Complete elimination of harmful and environmentally unfriendly gases

- Elimination of rotational, porous and fragile contaminant components

- Optimized scheme that allows short treatment time with maximum benefit

- Applicability to both continuous and batch processes

- Applicability to a wide range of casting processes and liquid metals

- Removal of oxides in addition to dissolved gases

Project Goals

- Provide the European light-alloys foundries with an environmentally friendly and safe means to improve the quality of their cast parts by applying an ultrasound degassing treatment.

- Establish a link between ultrasonic degassing parameters, melt quality and casting parameters, so as to develop a technology to be applied in different casting processes.

- Demonstrate the efficiency of the developed technology as compared with the currently used by using the Ultragassing prototypes on standard production conditions.

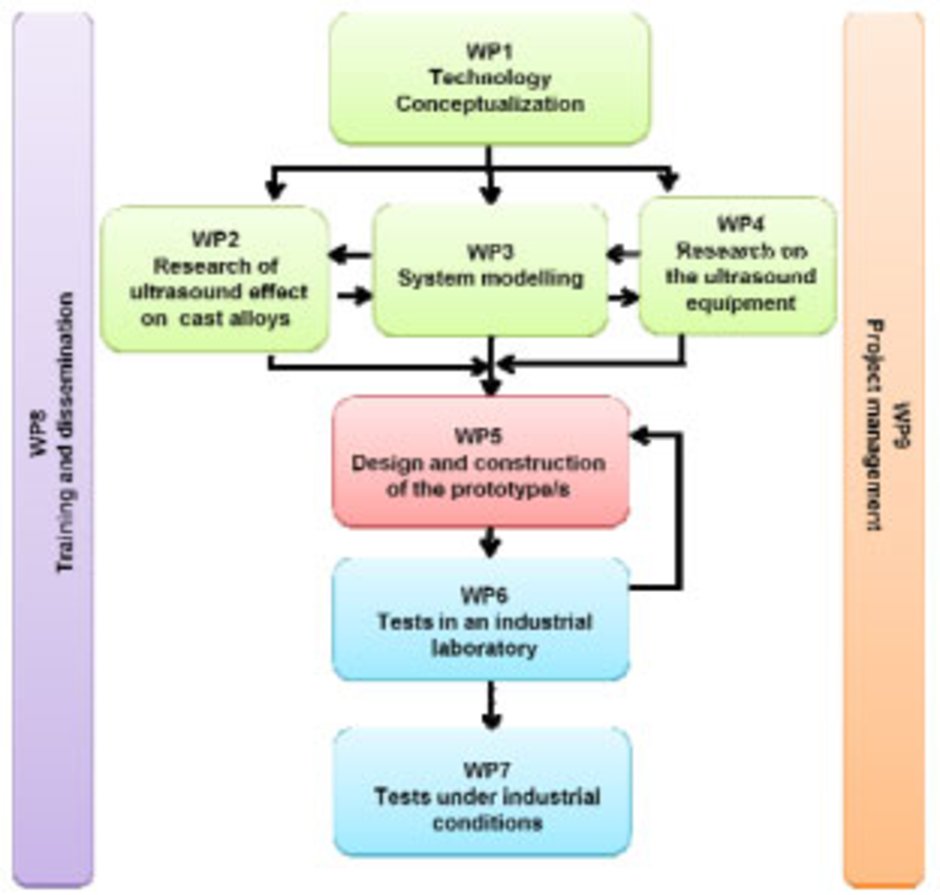

In order to achieve the expected results, the structure of the work plan lies in completing the following three phases:

- Phase 1: Research on ultrasound effect on molten metals and development of a numerical model of the process.

- Phase 2: Design and construction of prototypes.

- Phase 3: Prototype validation on industrial machines and in industrial casting processes.

The project, that started the 1st of October 2011 and with a duration of 24 months, will achieved its set objectives through the following 9 Work Packages (WP):

Contact:

Dr. Manel da Silva

Fundació Privada Ascamm

mdasilva@ascamm.com

Telf: + 34 93 594 47 00