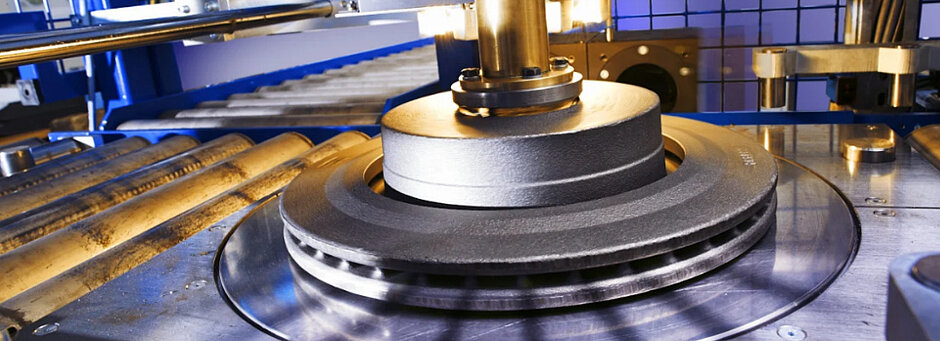

Brake discs are safety-critical components – the automotive industry demands that they are practically 100% defect-free. It repeatedely happens that entire batches have to be withdrawn because the client has found one single defective part or small quality defects. The financial damage is enormous; reputation is damaged.

There is only one way to avoid this: Automated inspection of the entire production. The complete surface as well as every single air vent in every brake disc must be fully examined on a reliable basis. But how do we separate the faulty parts from the parts which are free from defects, if there are only a few seconds available to do this?

The digital solution: DISC-INSPECTOR® fully automatically detects defects

For this, the DISC-INSPECTOR® by inspectomation systems GmbH, a wholly owned subsidiary of Laempe Mössner Sinto, is the ideal solution: He fully automatically detects surface defects as well as defects in the air vents and separates out defective parts onto a separate conveyor within the production cycle.

The system is extremely flexible: It tests brake disks of a wide variety of geometries (cars and trucks) and thus covers the requirements with its high variety of types and complicated product designs. This high-precision solution can be easily integrated, objectively, seamlessly and around the clock. So far, millions of brake discs have been successfully tested in the automotive supply industry. Laempe Mössner Sinto will present the DISC-INSPECTOR® at GIFA (Hall 17 Stand B40).

Advantages of DISC-INSPECTOR®:

• The systems realizes automated, objective, non-stop inspection – 24/7.

• Immediately ready-to-use: The complete system takes care of the separation, testing and rejection.

• The solution can be used flexibly for all brake disc types and vent geometries.

• Customers are able to determine test accuracy via an intuitive user interface.

• Thanks to solid construction, the system has a long service life and amortises very quickly.