- Gentle regulation, not rigid limitation

- Power demand cut by more than 20%

- Costs lowered without reducing production

- Transparent overview of power consumption

- Process improved by seamless monitoring

Reference report: current peak with Padicon reduced by 21% using the example of Reinhard Tweer GmbH, foundry in Bielefeld / Germany

The share of energy costs in gross value added has reached sad highs in Europe and especially in Germany. According to reports by the Federal Statistical Office, the share of energy costs in the foundry industry was recently over 25% of the gross value added. Reason enough to deal with this key benchmark of production processes and to show how Tweer GmbH in Bielefeld not only got a grip on energy consumption with Padicon but was able to significantly increase energy efficiency.

Reinhard Tweer GmbH in Bielefeld cuts peak demand by 21 per cent using Padicon.

Reinhard Tweer GmbH was founded in 1910 and today has a workforce of 350 at its Bielefeld site. Reinhard Tweer GmbH supplies the mechanical engineering and vehicle construction industry and also provides on-site casting. On average the foundry produces 27,000 tonnes of cast steel and ductile iron every year using six medium-frequency furnaces, which have a huge impact on the foundry’s energy costs.

No conventional load-shedding device can guarantee a reliable power supply for the six high-performance energy guzzlers. The solution: Padicon® parallel differential current control from Dr. Tanneberger GmbH.

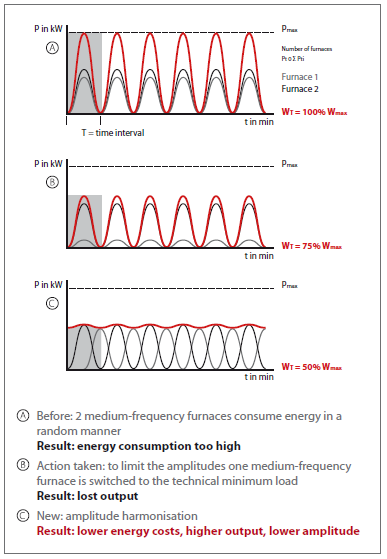

Padicon® replaces a rigid load limitation method with a smooth, process-oriented, adaptive control system.

The Padicon® principle

With power consumption as its command variable, Padicon® improves production processes at the foundry. High-energy processes are no longer independent, as before; instead, they are co-ordinated, balancing out peaks and troughs in demand against one another. Power demands undergo less fluctuation. The result: peak performance with no peaks in demand.

Improving power efficiency

Padicon® gives Reinhard Tweer GmbH a crucial advantage: all the foundry‘s furnaces can be operated simultaneously with no rise in power consumption. Peaks in electricity demand can be controlled precisely and sustainably. This not only guarantees that the workflow is uninterrupted, it also cuts energy costs without lowering production.

Record result for Padicon®

At Reinhard Tweer GmbH, Padicon® has set a new record: using the process developed by Dr. Tanneberger GmbH, the Bielefeld foundry cuts 21% off its peak demand. This figure means that Padicon®’s energy-saving potential has risen considerably over the last few years, and it sets new standards for future projects at Dr. Tanneberger GmbH.

The value of monitoring

Thanks to seamless monitoring, Padicon® reveals weaknesses in the production process. The process also provides a transparent overview of power consumption for every connected unit, at any time. New units can easily be hooked up to the system later.