A new magnesium-treatment practice that improves the production of ductile iron will be featured in Elkem Foundry Products booth at CastExpo ’13 in St. Louis on April 6-9, 2013. The new practice gives a quieter reaction, increases magnesium recoveries, and lowers costs.

A videotape comparing the new practice with conventional ductile-iron treatments will be shown at Elkem’s CastExpo booth. Elkem’s metallurgically trained sales representatives will also be available to discuss the new treatment process as well as Elkem’s design improvements that enhance its benefits. Elkem’s representatives can also provide information on the company’s unique line of inoculants and nodulizers designed to optimize gray- and ductile-iron properties.

More Efficient Magnesium Treatment of Ductile Iron

The new magnesium-treatment practice uses Elkem’s LAMET® nodulizer and TOPSEED™ cover alloy to treat molten iron and create the desired ductile-iron nodular-graphite microstructure. When iron is poured into a specially designed ladle containing these alloys, the normally explosive reaction with magnesium does not take place right away. Once it starts, the reaction is much quieter and takes almost twice as long as conventional treatments with less spilling, fume, and slag. This slow reaction allows foundries to recover more magnesium from the nodulizer and obtain a well-inoculated iron with good nodularity.

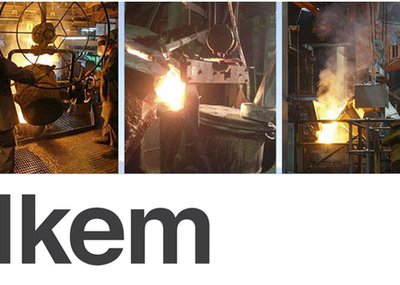

In typical photos below, the quieter reaction obtained from using Elkem’s LAMET® nodulizer and TOPSEED™ cover alloy is compared with a conventional practice using magnesium ferrosilicon and 75% ferrosilicon. The photos were taken 15 seconds and one minute, respectively, after iron started to pour into the treatment ladle.

By taking advantage of the ladle-design improvements offered by Elkem, ductile-iron foundries can also reduce temperature losses, fill the ladle faster, delay the release of magnesium, significantly improve magnesium recoveries, and obtain desired ductile-iron microstructures.

Complete Line of Inoculants and Nodulizers

Elkem’s CastExpo booth will also feature the company’s complete line of high-performance inoculants and nodulizers in the full range of grades and sizes needed to produce gray and ductile iron. These specialty products offer many foundry benefits, including their ability to control graphite shape and size, influence the ferrite/pearlite matrix ratio, eliminate surface chill and internal carbides, minimize shrinkage, optimize mechanical properties, and increase machinability.

For example, Elkem’s high-performance SUPERSEED® inoculant maximizes chill reduction in gray iron, giving superior machinability, reduced shrinkage, and higher strength in castings. Also, Elkem’s thin-cast LAMET® nodulizer gives higher nodularity in ductile-iron castings than regular magnesium-ferrosilicon. The alloy also reduces scrapped castings from shrinkage, gives a better machined surface, and produces higher strength castings compared to conventional nodulizers.

Elkem’s extensive research-and-development program is continually working on new high-performance, problem-solving materials that will improve the production and properties of gray and ductile iron.