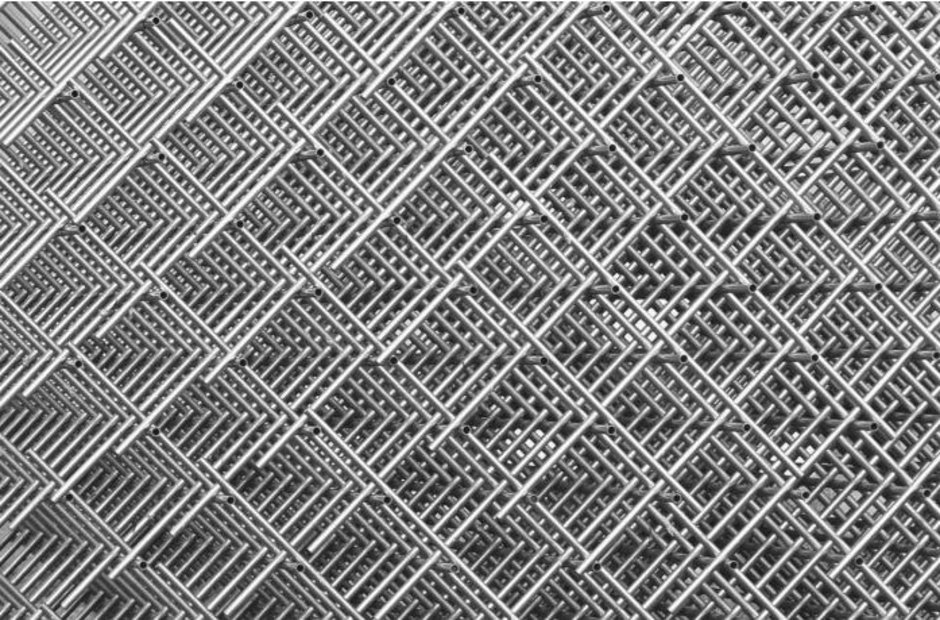

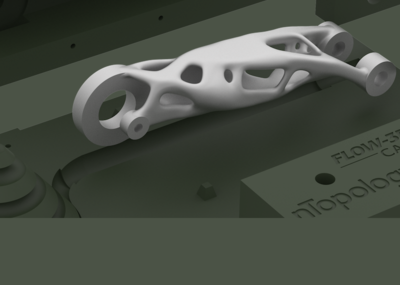

Enable uses a new technology called Additive Casting for the manufacture of metal parts. The process uses moulds made via additive manufacturing to cast high-quality production parts from over 130 different metals, including magnesium. This novel method eliminates the need for expensive tooling and allows manufacturing business to re-shore productions to the UK, leading to a reduction of CO2 emissions and enabling manufacturing business to innovate quicker, reduce inventory and implement a digital supply chain approach for metal parts.

Additive Casting has proven to be particularly suitable for the automotive industry, as it offers a new design freedom for engineers to design better, lighter and more cost competitive metal components – large or small – by enabling part optimisation, light weighing of parts and eliminating costly and inflexible tooling.

“We are delighted to be working with Enable Manufacturing as part of our Technology Developer Accelerator Programme (TDAP),” says Head of SME Programmes at the Advanced Propulsion Centre, Josh Denne. “The past 12 months have been difficult for the automotive sector, with COVID-19 and shortages of some key materials, it’s been challenging for all parts of the supply chain, not least those small to medium enterprises trying to turn their green automotive innovation into a commercially viable product.

However, the TDAP is not just about funding the technology development. APC are keen to ensure that these ideas turn into a commercial success as Josh goes on to explain: “The winners of this competition demonstrated that their technology enables the shift towards net-zero emissions vehicles, but our aim is to provide successful applicants with a systematic, phased approach to building their businesses – a 360-degree programme of support to help great ideas flourish in a commercial space.

Being part of this programme is a great opportunity for Enable Manufacturing and will be crucial in further developing the Additive Casting technology for the automotive sector in its quest to zero-emission manufacturing.

The funding is provided by the Department for Business, Energy and Industrial Strategy, and is being made available under the Advanced Propulsion Centre (APC) Technology Developer Accelerator Programme (TDAP).

Under this program, each company will receive up to £135,000 to help take their concept a step closer to being used by the automotive industry and helping drive the UK towards a net-zero emissions future.

Source: www.ivtinternational.com by Tom Stone is Editor of the iVT brand.