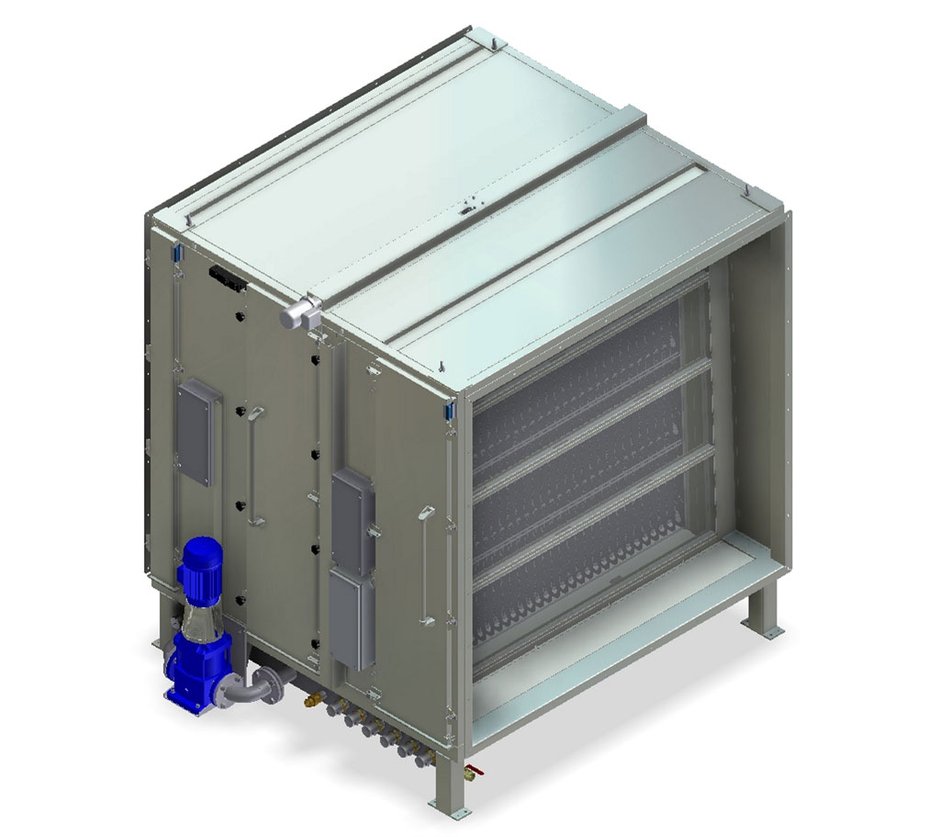

The new ULTRAVENT® large exhaust air filter system

Once again KMA Umwelttechnik sets new standards in energy efficient exhaust air filtration and brings a new ULTRAVENT® model of the type 30,000H (with an air flow of 30,000 m3/h) onto the market. The new model is not only convincing through its enormous capacity, but also through its compact design, which can be seen as an exception compared to other air purification systems of the same filtration capacity. The special feature of the new system is the combination of all previous advantages of the KMA ULTRAVENT® models with newly added innovations, which are necessary due to the high performance capacity. By adapting the high-quality, high-performance and durable components of the filter system to the increased capacity, the probability of default is reduced to a minimum so that the reliability and availability of the system is expanded to the highest level. In addition the air flow is adapted to the capacity as well to enable even further energy savings compared to the existing ULTRAVENT® filters. In this way the specific energy consumption is reduced up to 8 percent. The very low pressure loss is marking a significant saving potential in the annual cost of operation. Customer´s needs are important sources for KMA´s development activities. That’s why the new ULTRAVENT® large size filter system offers an outstanding ease of use.

In terms of energy efficiency, the new ULTRAVENT® of the type 30,000H will continue offering the well-proven equipment features of KMA. All ULTRAVENT® ventilators are equipped with a frequency converter for fan speed control. The speed can be adjusted according to the requirements. Even a small reduction in speed leads to significant energy savings. Optionally the ULTRAVENT® filter system can be combined with an integrated heat recovery system and a heat pump. Thus, over 85 percent of the energy contained in the waste air can be recovered and reused again. In addition the ULTRAVENT® exhaust air filter system offers a flexible and cost effective solution by means of its modular filter elements. Beside demister units and electrostatic precipitator cells for separating emissions, ULTRAVENT® filter systems can be equipped with an activated carbon filter or with UV lights for odour removal. The integration of the optional automatic filter cleaning system (CIP) ensures a minimal maintenance level and a maximum user comfort.

Although the new ULTRAVENT® model can be delivered only from the fourth quarter of 2012 on, numerous customers are already interested in the new system. Powered by innovation KMA´s task is to combine separation efficiency and energy efficiency to the highest degree and to prove that environmental sustainability does not go against cost effectiveness. In fact these two factors complement and benefit one another.

also available in <link record:tt_news:12075 internal-link>![]()

![]()