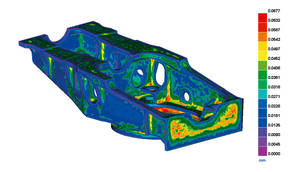

ESI has developed over the years a set of applications for the foundry industry to optimize processes and to improve part quality. ESI’s Casting Simulation Suite (including ProCAST & QuikCAST) allows predictive evaluations of the entire casting process including: filling and solidification defects; mechanical properties; and, complex part distortion. It enables rapid visualization of the results of casting and thus allows correct decision-making at an early stage in the design of a manufacturing process. ESI has developed over the years a set of applications for the foundry industry to optimize processes and to improve part quality. ESI’s Casting Simulation Suite (including ProCAST & QuikCAST) allows predictive evaluations of the entire casting process including: filling and solidification defects; mechanical properties; and, complex part distortion. It enables rapid visualization of the results of casting and thus allows correct decision-making at an early stage in the design of a manufacturing process.

ESI has developed over the years a set of applications for the foundry industry to optimize processes and to improve part quality. ESI’s Casting Simulation Suite (including ProCAST & QuikCAST) allows predictive evaluations of the entire casting process including: filling and solidification defects; mechanical properties; and, complex part distortion. It enables rapid visualization of the results of casting and thus allows correct decision-making at an early stage in the design of a manufacturing process.

"ProCAST recent developments prove to be excellent for predicting the microstructure and the basic mechanical properties of casting materials,” said Dr. Antton Meléndez Arranz, Metallurgist at Tecnalia. “Using the microstructure module, the simulation of local graphite expansion is possible with a sensitively higher accuracy for shrinkage defects prediction. The microstructure module opens up a new line of possibilities and makes other types of analyses possible, particularly in relation to metallurgical quality level adjustments, according to the inoculation parameters in simulation."

"ProCAST recent developments prove to be excellent for predicting the microstructure and the basic mechanical properties of casting materials,” said Dr. Antton Meléndez Arranz, Metallurgist at Tecnalia. “Using the microstructure module, the simulation of local graphite expansion is possible with a sensitively higher accuracy for shrinkage defects prediction. The microstructure module opens up a new line of possibilities and makes other types of analyses possible, particularly in relation to metallurgical quality level adjustments, according to the inoculation parameters in simulation."

"We are pleased to announce the release of our Casting Simulation Suite 2010,” said Marco Aloe, Casting Product Manager at ESI Group. “Our growing and faithful installed base demonstrates the relevancy of our solution for foundries, whether they require a quick estimate or a more advanced and complete diagnosis. Our goal remains to develop tailored tools to help foundries efficiently design the best quality part and meet performance criteria. Included in version 2010 are developments in microstructure, stress, optimization and interfaces to specifically meet our customers’ challenges."

Click here for further Information and Contact to ESI Group in our Suppliers Profile