In the field of SG - DUCLTILE - NODULAR iron castings demand is growing and FOMET has developed a new pouring furnace for production of castings in Nodular Iron.

In the field of SG - DUCLTILE - NODULAR iron castings demand is growing and FOMET has developed a new pouring furnace for production of castings in Nodular Iron.

The production of quality castings in "Nodular-iron" poured manually into moulds on automatic indexed green-sand moulding lines, is foremost in a series of critical foundry operations.

That is the main reason why many large, medium and even small size foundries have started to demand and use automatic systems to pour Nodular iron on their moulding lines.

FOMET specialise in the field of pouring furnaces, and are one of the market leaders with over 48 year experience. They have installed several hundred furnaces equipped with automatic pressure pouring systems with stopper-rod control for pouring grey, malleable and other special cast-irons.

The FOMET technology incorporated in the pouring furnaces have made pouring easy, simple and applicable not only on new moulding lines but also as retrofitted on already installed moulding plants.

To develop and design this furnace FOMET has exploited its own experience as manufacturer of pouring furnaces, making specific research in this field and verifying results in co-operation with existing clients and metallurgical technicians. Moreover, comparing data and examining the available technical papers of important Italian and International technical associations as well as those of competitors, have all contributed to recent developmentsl.

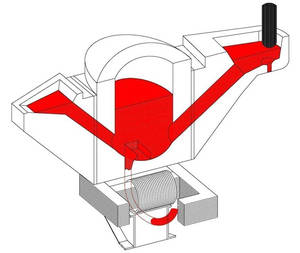

The new pressure-pouring furnace PRV is a vertical channel furnace with the inductor flanged to the bottom of the furnace body. The cover to seal the furnace vessel is equipped with a small hatch so that the furnace can be de-slagged and also to allow the inductor to be rodded, as required.

The new pressure-pouring furnace PRV is a vertical channel furnace with the inductor flanged to the bottom of the furnace body. The cover to seal the furnace vessel is equipped with a small hatch so that the furnace can be de-slagged and also to allow the inductor to be rodded, as required.

The pouring furnace is designed for operating with inert gas like Nitrogen to pressurize the furnace and the cover is gas tight. The substantial refractory thickness makes a perfect supporting face for the cover sealing ring; particularly as pressure sealing is one of the known problems in the coreless furnaces.

The furnace is equipped with flanged fill and pour siphons, which are easily interchangeable and simple to maintain.

Unlike the special coreless pressure pouring units, where the useful power varies according to the metal level height relative to the induction coil, here in the PRV, the full super heating capability (useful power) is always available whether the furnace is full or on minimum heel.

The PRV inductor power is also managed in a way to minimise the build-up inside the channel. The need for changing the inductor is simply programmed by monitoring the inductor efficiency diagram indicator (cosphi operating range). Also the cleaning of the fill and pour siphons is simple, they are straight and without bottom bend angle entering in the furnace vessel. Changing of the siphons is even possible with metal inside furnace.

The PRV inductor power is also managed in a way to minimise the build-up inside the channel. The need for changing the inductor is simply programmed by monitoring the inductor efficiency diagram indicator (cosphi operating range). Also the cleaning of the fill and pour siphons is simple, they are straight and without bottom bend angle entering in the furnace vessel. Changing of the siphons is even possible with metal inside furnace.

Another big advantage of the PRV induction channel furnace versus the coreless pouring furnace is the good electrical and thermal efficiency and hence the low overall energy consumption in continuous operation.

The PRV induction coil cooling system is unique, by air (no water), so the furnace does not need the special water-cooling system which is necessary for coreless furnaces. The efficient refractory lining maintains the thermal losses to a minimum to guarantee big energy savings. In comparison other types of furnaces, like the coreless furnace, these require a bigger power input for maintaining and superheating the metal. It is also difficult for them to control metal temperature and the refractory lining life which requires on-going maintenance is also short and subject to other problems.

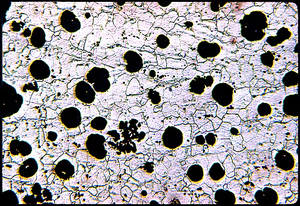

In processing Nodular iron the treatment methods which use pure magnesium, are generally to be recommended.

According to customers data initially the gas atmosphere has no effect on the rate of alloy fade. (Mg fade) However after stabilization, the rate of melting loss (fade) is reduced considerably, thus assuring that the molten metal remain ready for pouring with a sufficient Mg content over the full holding time of up to 8 hours.

Maintenance operations are simple and kept to minimum requirements to maintain the furnace efficiency and not having a water-cooling circuits, is a great advantage and cost saving.

The pouring furnace can be equipped with all the standard FOMET options like "Laser system" for controlling the level in the pouring channel, the CCD Vision system for controlling the mould cup filling level, late metal stream inoculation, furnace weighing and an automatic skip charger for the furnace charging ladle.

If required a furnace automatic nozzle centring system for the the pouring cup is also available and is sometimes necessary in vertical flask less moulding lines.

Other than Teksid Spa and Amtek in India, the following "automotive" companies have chosen FOMET equipment: ACI- Group Renault LeMans - Brazil, Rassini Frenos SA - Group San Luis Rassini , Autometals SA -Spicer-Dana Group, Tisamatic de CV SA - Mexico, GKN Automotive - China, and Ashok Iron Works , Sakthi Auto and many others.