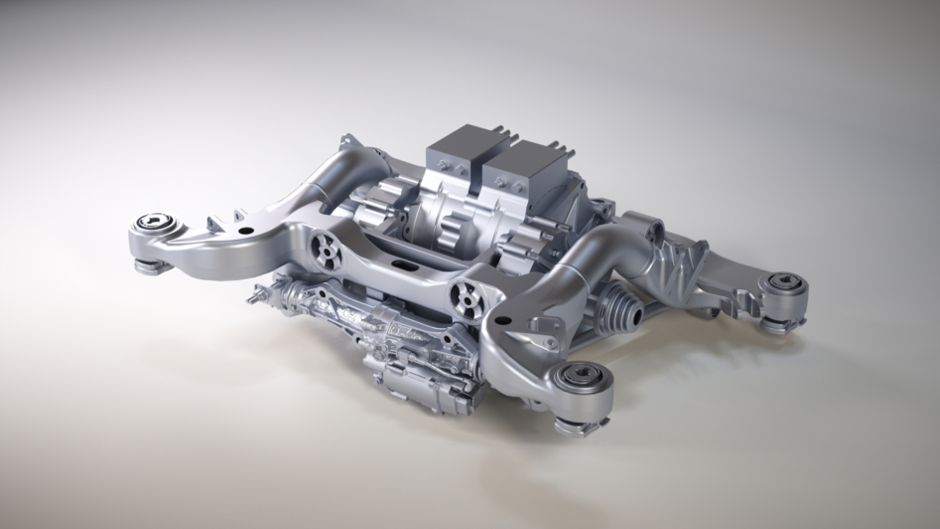

In meeting advanced technical requirements, overseeing the complete development process and drawing on experience that has been acquired over many years, Nemak is able to offer tailor-made solutions for complex chassis applications. At EUROGUSS 2020, this comprehensive development competence was shown using a subframe prototype – a product that Nemak has developed especially for these demonstration purposes.

There are as many chassis out there as there are vehicle types. For some customers, Nemak manufactures components according to OEM specifications; for other customers, the lightweight construction specialist develops solutions from scratch. In such cases, concept solutions are devised based on different parameters and requirements. These particularly focus on performance, weight and tolerance characteristics – not to mention the efficient use of the available assembly space. At EUROGUSS 2020, a prototype weighing a mere 17.5 kilograms was exhibited to give visitors the opportunity to gain insights into these challenges.

“The subframe prototype is a product that we can use to show examples of some of the challenges we face in developing a solution concept – and how we solve them,” says Dr. Christoph Viechtbauer, Global Product Development Manager at Nemak in the Vehicle Structures division. “The advantage we offer our customers is that we cover the entire development process spanning the concept, design, development, validation and production phases – all from a single source.”

“This begins with choosing the concept and design that is right for the customer,” explains Dr. Christoph Viechtbauer with respect to the process chain. Next come topology optimization, shape optimization as well as an investigation of the fatigue behavior of the applied materials. At the end of the process chain stands the finished prototype and, finally, a test and validation phase. From the initial idea to the finished prototype, the entire product development process comprises up to 10 development steps.

“Of course, aspects such as crash behavior and stiffness play an important role,” says Dr. Christoph Viechtbauer. “We develop different products based on different approaches.” Two concepts were defined for the subframe prototype: an ultra-lightweight solution and a cost-optimized version. “This way, we can develop the optimum solution together with our customers, based on tailor-made technical concepts.”