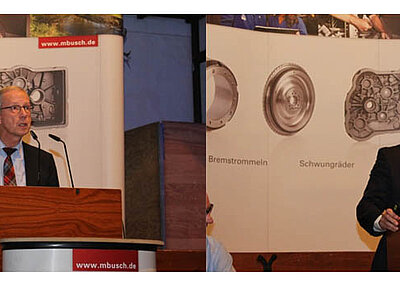

Busch continues to invest in automation. In the Bestwig plant, a completely redesigned, interlinked production line for processing truck brake discs has now been put into operation in Hall 7, which has also been newly built. Four million euros were invested in a new 4,100 m² hall and an ultra-modern processing line for four million euros.

The new system is technically designed in such a way that, with the same operating team, double the output of 250,000 ready-to-install brake discs per year compared to the existing systems.

The fully automated line includes unmanned loading with an integrated Poka Yoke, supported by a camera visualization. Poka Yoke is a Japanese term for systematic error detection and avoidance. The core of the production line is made up of four lathes, a dynamically testing measuring unit, needle embossers to ensure traceability and three drilling systems with subsequent tactile robot measurements to identify the machining features. These systems are linked via various handling devices and robots.

In the past four years, Busch has already invested a mid-double-digit million sum in the foundry in Wehrstapel. The expansion at the Bestwig location has now been continued as part of the MB 2022 strategy, after investments were made in a new line for machining flywheels last year.

"The aim is to make Busch fit for the future with regard to Industry 4.0, quality, capacity and products at both locations, even in times of crisis," says Managing Director Andreas Güll. Busch currently employs around 530 people with a turnover of 110 million euros.