Global engineering group GKN has signed an MoU with Arcam AB, Concept Laser and GE Additive with a view to collaborating on additive manufacturing. Under the agreement additive services and machines will be provided to GKN. GE Additive as well as its affiliated firms will also be supplied with additive manufacturing powder by GKN.

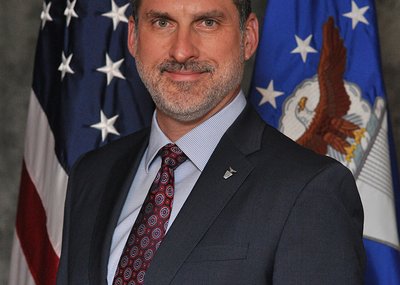

“GE Additive and GKN both understand the transformative power that additive manufacturing will have in the aerospace and automotive industries. Additive machines from Concept Laser and Arcam will bring tremendous value to this GKN relationship,” said Mohammad Ehteshami, the general manager and Vice President of GE Additive.

Preferred supplier status

The agreement will also see GE Additive as well as its affiliates become the preferred suppliers of additive manufacturing machines both to GKN and to GKN’s affiliates. The engineering consulting team of GE Additive will help GKN as well as its affiliates to accelerate and industrialize additive manufacturing machines.

On its part GKN will, with regards to powder bed machines, become the production and development partner of GE Additive in order to access new opportunities existing in the market. GKN will also become the non-exclusive preferred powder supplier to the industrial businesses of General Electric as well as to GE Additive.

3D printing

In additive manufacturing which is also referred to as 3D printing, digital designs derived from CAD software before building on specialized additive manufacturing equipment from metal powder. Typically additive components are more efficient, more durable and lighter compared to traditional forged and casting parts since they can be built as one piece and thus requiring less assembly, joints and welds. And due to the fact that additive parts are developed right from the initial stages, there is less waste. With additive manufacturing the design possibilities of engineers are dramatically expanded since the traditional manufacturing restrictions no longer exist.

For a long time now General Electric has been leading in additive manufacturing innovation. General Electric also recently invested $1.4 billion in Arcam and Concept Laser. In the last decade the industrial conglomerate has also invested a total of $1.5 billion in additive and manufacturing technologies. During this time the conglomerate has been awarded 346 patents in the area of material science. GE Additive was established last year with the aim of making the unit a leading supplier and provider of additive materials, services and technology for businesses and industries worldwide. Currently GKN has a presence in more than 30 countries.

Source: Macondaily.com

×