If you speak to anybody from the world of motorsport about engines and transmissions, there is one name that is immediately associated with casting design and rapid prototyping - Grainger & Worrall. Their unrivalled experience in F1 and WRC championship engine and transmission programs can be demonstrated by the fact that all 20 cars on the LMP2 grid at Le Mans in June 2018 were using Gibson GK428 engines, cast by Grainger & Worrall.

However, motorsport is only one part of their expertise, as they offer clients extensive knowledge in Casting Design and Engineering, Tooling Design, Machining and Prototyping. Grainger & Worrall’s specialist prototype aluminium foundry approaches product development by adding value, delivering successful high integrity precision sand castings for automotive engines, aerospace components and other industrial markets. The world is demanding ever-lighter, ever more efficient means of propulsion, resulting in increased prototype demands and increased quality control requirements. To meet the demands of approximately 300 New Product Introductions including niche volume and motorsport supply annually, Grainger & Worrall recently purchased a Creaform HandySCAN 700 from Measurement Solutions, official distributor of Creaform in Great Britain.

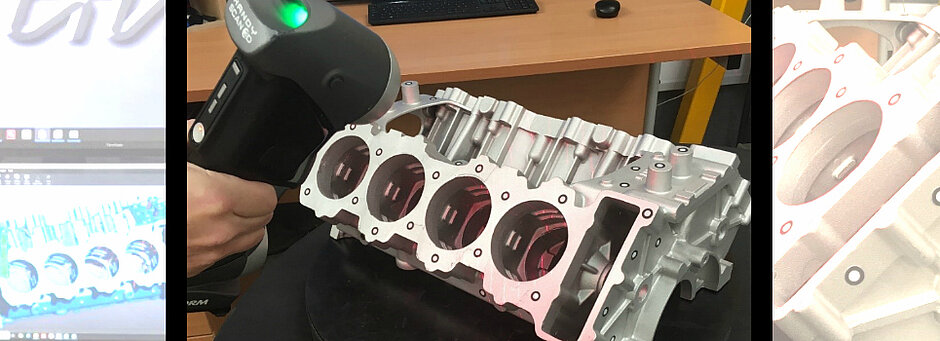

Although already equipped with traditional gantry CMM’s (Co-ordinate Measuring Machines) advanced industrial CT scanning (Computed Tomography) and white light scanning systems, the increasing complexity and persistence to push the limits of possibility has driven a need for both increased capacity and capability. The requirement to spend time preparing surfaces of castings with powder spray, which has always been difficult with projected light scanners, all served to drive their decision to purchase the Creaform HandySCAN 700. David Lang, who was integral to the decision-making process, comments “The HandySCAN 3D ticks many boxes for us. Not requiring powder spray is an obvious benefit in terms of time savings, both before and after scanning. We were spending several thousand pounds annually on spray, which is an inefficient and unnecessary cost, and add to that the associated costs incurred during the ‘shot blasting’ process to clean the castings after scanning”.

The HandySCAN 700 utilises seven red laser crosses which offers a large field of view and a capability to capture data extremely fast. Mr. Lang continues, “After testing the HandySCAN 3D it was obvious to us the seven laser crosses feature allowed for very fast data capture, with the addition of a single laser line to capture areas within deep pockets. We also found the HandySCAN 3D to be of high accuracy and comparable to our existing equipment”.

In house quality management ensures the effective design of processes which verify the customer’s needs. This has helped to ensure that Grainger & Worrall are known globally as the leading supplier of prototyping services in structural Powertrain Components, and an exceptional supplier of Castings and Machining for Specialist Low Volume Cast components. It is these evolving processes that have provided Grainger & Worrall with opportunities to continually assess and upgrade their equipment needs.

As is often the case with new technologies, once in process, users get to explore the full benefits on offer. Mr. Lang adds “As we assessed the product further, additional benefits came to the forefront. The ability to scan with a ‘handheld’ portable solution was significant. The fact the HandySCAN 3D and all accessories fit into a small carry case means it is quick and simple to take the shop floor and start inspecting. Whether it be a large piece of tooling or a sand mouldpack being assembled, we can now take the scanner on location, set-up and be finished within the hour. Before purchasing the HandySCAN 3D this task would have been much more challenging and usually resulted in moving components to the Metrology room, which often was impracticable”.

As with any company constantly investing in new technology, the availability of training, system implementation and after sales support is a very significant part of any decision to purchase. Aftersales support has always been a huge part of Measurement Solutions DNA and a key to their success, having recently celebrated their 20 Year Anniversary. Andy Warriner, Area Sales Manager for Measurement Solutions, comments “The team at Measurement Solutions provide a complete training course, ranging from two to four days depending upon the application, either inspection or reverse engineering. Additionally, we have Applications Engineers dedicated to Creaform products, who are always on hand to add further support if required after the initial training”.

Creaform at GIFA 2019: Hall 13, Booth B35