Before this innovation for the filtration of cast parts in the field of steel and large-scale casting, foundrymen had to rely on ceramic filters made from foam ceramic materials based on zirconium oxide and silicon carbide or on graphite-based filters. However, both these filter types cause considerable difficulties because they are very fragile and thereby very expensive. Far too often, users found themselves struggling with uncontrolled filter breakage and extreme variations in flow characteristics.

Before this innovation for the filtration of cast parts in the field of steel and large-scale casting, foundrymen had to rely on ceramic filters made from foam ceramic materials based on zirconium oxide and silicon carbide or on graphite-based filters. However, both these filter types cause considerable difficulties because they are very fragile and thereby very expensive. Far too often, users found themselves struggling with uncontrolled filter breakage and extreme variations in flow characteristics.

For many years, pressed ceramic filters with round holes have been the state of the art in the production of smaller cast pieces. These filters are already well on the way - because of their extraordinarily good filtration performance resulting from their controlled mechanical and hydraulic properties - to leaving foam ceramic filters far behind. Until now these filters were available only for casting temperatures up to 1450°C and for flows up to 500 kg per filter. Nevertheless, because of the mechanical robustness of this type of filter, they are already used very successfully in large-scale casting involving cast weights of over 80t. However, a large number of filters have to be used for each cast piece and the design of the gating system ends up being correspondingly complex.

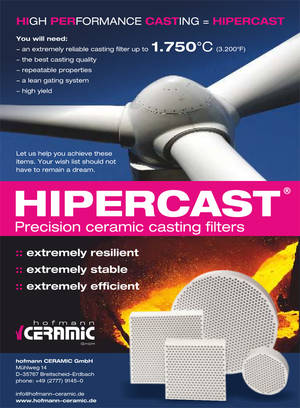

With the development of a new high-performance mullite-based ceramic material with the type designation HIPERCAST, hofmann CERAMIC now has a pressed filter that can achieve levels of performance hitherto considered beyond the capability of individual filters. Castings have been successful completed where casting temperatures up to 1750°C were withstood and flows up to 15t for grey cast iron and 9t for ductile cast iron per filter were achieved. At the moment, the limits for the performance of these filters are unknown as we have not yet been able to destroy a filter so far in our tests. It appears that the determining factor for the limit may be flow speed (creation of turbulence) and not the mechanical and thermal robustness of the filters.

This takes the foundrymen into a completely new world:

- Hydraulic properties are more accurately calculated with precise geometries.

- Mechanical properties provide large reserves of fracture strength.

- Filtration performance at the highest level, calculable and demonstrable.

- Savings potential for circulating material and sand is extremely high.

The new HIPERCAST filters will be presented by hofmann CERAMIC at the following trade fairs in 2012:

- IFEX FOUNDRY TECHNOLOGY Bangalore/India 2-4 March

- AFS METAL CASTING CONGRESS Columbus/Ohio/USA 17-20 April

- METEF-FOUNDEQ Verona/Italy 18-21 April

- METAL + METALLURGY Beijing/China 9-12 May

- METALLURGY-LITIMASH Moscow/Russia 25-31 May

- ANKIROS Istanbul/Turkey 13-16 September

| hofmann CERAMIC GmbH is a leading supplier for "Ceramic filters", "metalfiltration" , "Chills" and more. For further information and contact details click here: hofmann CERAMIC GmbH |