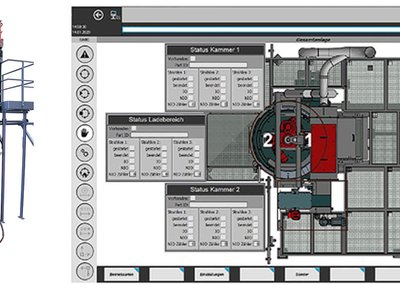

With its highly flexible design the RDGE 1000-4 can handle all the important blast cleaning tasks in the die-casting and general foundry industry, be it de-sanding, de-burring, surface texturing, cleaning and surface finishing in continuous flow operation. The RDGE 1000-4 guarantees not only absolutely stable but also exceptionally cost-efficient shot blasting operations! The die-castings are transported through the shot blast machine on a highly wear-resistant one-piece wire mesh belt with a width of 1,000mm.

In its standard version the machine is equipped with four (4) Gamma 300G turbines. Alternatively, the system can be supplied with eight (8) turbines. The optimal turbine placemen on the roof and the bottom of the blast chamber ensures that even the most complex work pieces with pockets and undercuts can be reliably blasted across the entire belt width.

A major reason for the excellent shot blast results is the “Y” shape of the throwing blades used in the high-performance turbines designed by Rösler.

Compared to conventional turbines the innovative blade design in the Gamma turbines significantly increases the throwing and impact speed of the blast media. The effect is an up to 20% higher blast performance and, at the same time, a lower energy consumption. Even when blast media with a relatively low weight, such as aluminum cut wire, is used, the blast results are achieved within considerably shorter cycle times. This helps not only to reduce the operating costs, but also to make the whole shot blasting process more sustainable.

In addition, the fact that both sides of the throwing blades can be used, saves valuable resources and lowers the costs even further. The throwing blades can be exchanged with a special quick-change system without having the dismount the turbine from its housing.

Rösler Oberflächentechnik GmbH at the Euroguss exhibition on January 18 – 20, 2022 in Nuremberg, hall 9, booth 9-203. www.rosler.com