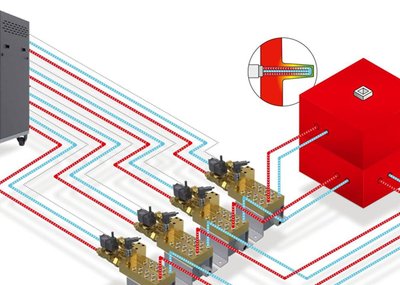

Pressure die casting is a manufacturing process for producing devices ranging from medical devices to industrial equipment. However, it’s proven challenging to make die tools for Pressure Die Casting (PDC) that have efficient cooling channels using traditional methods. Die tools in standard production have straight-line cooling channels that are degraded.

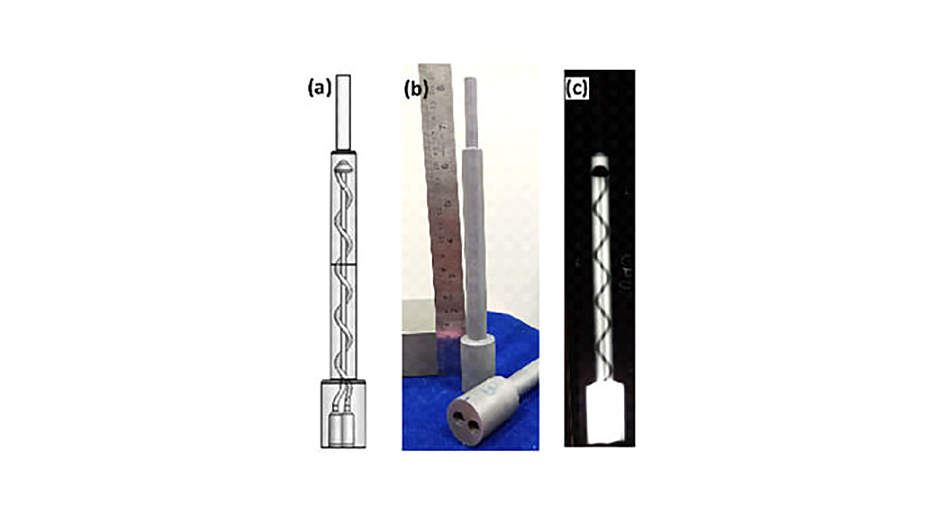

A team of scientists at the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI) has developed a manufacturing process for steel alloy powder that can act as a tool for creating efficient cooling channels for pressure die casting. This manufacturing process for a steel alloy powder called AISI H13 can serve as a tool for efficient cooling channels or conformal cooling channels (CC) for pressure die casting (PDC).

These CC systems have a lot of potential as a replacement for traditional cooling systems since they can deliver more uniform and efficient cooling effects, which significantly improves product quality and efficiency. The cooling channels can be given any shape using the additive printing method, as long as they can carry out the cooling efficiency.

The findings open a new world of design innovation that the conventional manufacturing process previously impossible to achieve.

Source: www.techexplorist.com