German traditional foundry with high automation potential

The traditional German foundry Schmiedeberger Gießerei has a remarkable company history. Cast products have been manufactured in Dippoldiswalde for over 600 years. With a wide range of approx. 3500 "living models" in the range from 50 g to 400 kg, Schmiedeberger Gießerei supplies well-known customers from the mobile hydraulics, mechanical engineering and energy sectors such as Bosch Rexroth or Liebherr. For quite a time, Schmiedeberger Gießerei had been looking for an automated solution for casting finishing. Until recently, the casting finishing work at Schmiedeberger Gießerei had been carried out manually at several locations. The wish to automate this work came from the following challenges: In addition to high process costs, machining results in manual fettling vary depending on the operator, and it is increasingly difficult to find personnel for the physically demanding work. An important requirement of the management was that the machine could be operated easily and quickly by existing foundry personnel without time-consuming training. In addition, the foundry attached great importance to having a German contact with reliable service within easy reach.

New MAUS product line meets customer requirements

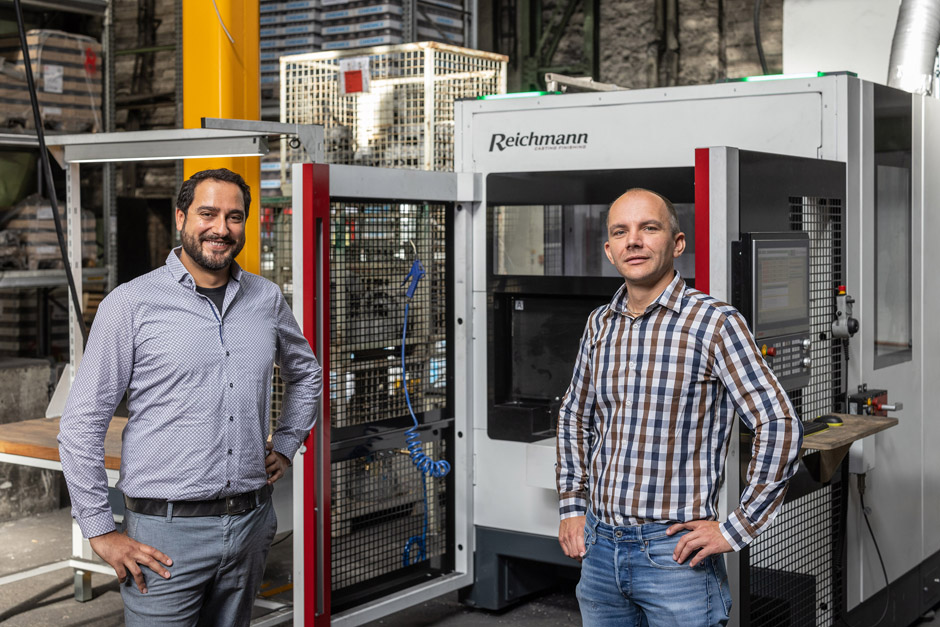

When contacting the Reichmann company, it quickly became apparent that the philosophy and vision of both companies matched very well in terms of quality standards and focus on regionality. In addition, Reichmann Casting Finishing offered exactly the right solution for the customer's problems and requirements with the new Maus product line.

The Maus 600 Casting Finishing Center convinced with the easiest programming without prior knowledge, the high flexibility for different castings, the fast installation and the constant high quality grinding results with very short cycle times per casting. In addition, with the German family-owned company Reichmann & Sohn, Schmiedeberger Gießerei has chosen a partner that offers everything from a single source - from consulting to after sales. "The Reichmann team advised us very well right from the start and all questions and concerns were answered directly. For us, the machine from Reichmann was the best choice because the overall package of performance and price is simply right," says Dr. Falko Uyma, Technical Manager at Schmiedeberger Gießerei

Extremely short integration and training time inspires staff and management

Thanks to the good cooperation and the great interest of the customer, it took only three days to install the machine at the customer's site, create a joint program and optimize it for production. Besides, the operators could be trained in this time, despite almost no previous knowledge of NC programming, and the machine was handed over to production. Already in the first weeks after the machine installation, Schmiedeberger Gießerei was very satisfied with the decision for this automation solution.

"The machine has met our requirements and solved our problems. Currently, we have programmed two different castings with the MAUS 600 and are achieving time savings of more than 50 percent. We are already looking forward to the new MAUS 900 in November," says Dr. Uyma.

The next machine from Reichmann will be delivered in the fall of 2022. The larger and more powerful Maus 900 casting finishing machine will complement the already operating Maus 600 for processing larger and heavier castings. With both machines, Schmiedeberger Gießerei is able to automatically grind approx. 80 percent of the product range, which significantly increases productivity and cost-effectiveness.

The new MAUS product line makes the step into automation particularly easy

"The high flexibility of our Maus Line is particularly attractive in this target group due to the high change intervals of the castings. With the IIoT-capable control system the foundry is also optimally positioned for the future," says Rafael Dineiger, Sales Manager International at Reichmann. The easy setup of the machine, the optional laser measurement system and the attractive financing offers from Reichmann also make it very easy for other foundries to take the first step into automation with higher output and quality.