With the launch of the integrated management system for its Lammersdorf production site OTTO JUNKER not merely meets the increasingly exacting demands of customers and partners in the equipment construction and foundry business but also goes for a clear improvement of its own processes in the fields of energy management, environmental and occupational safety.

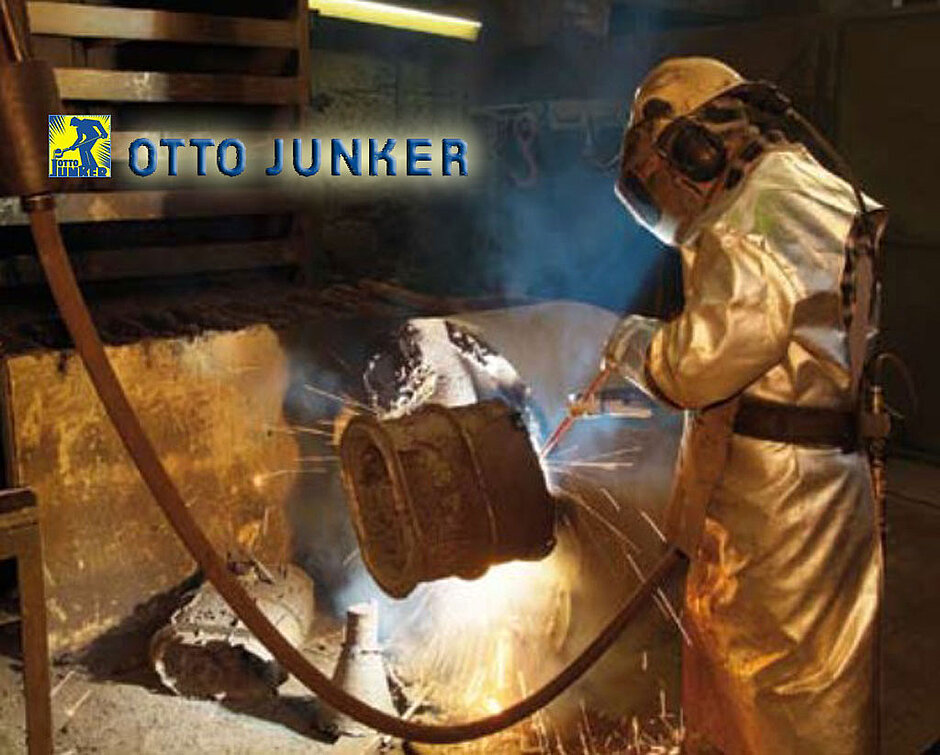

Production processes, specifically in the foundry but also in equipment construction, have a direct impact on the environmental, energy and occupational safety situation and are therefore of specific interest. The management system is built around the creation and continuous upgrade of risk assessments and on the evaluation of environmental and energy criteria. For our equipment construction activity it is not just in-house production processes which matter; the requirements on environmentally sound design which is consistent with safety standards and hence, in line with CE principles, are of particular relevance.

The system is intended to yield a clear definition of the respec- tive legal requirements and applicable regulations and, more specifically, to regulate the implementation thereof at the operational level in a manner that is both unambiguous and traceable. As a result, it is intended to provide superior transparency and clarity in mapping the requisite activities and their realization.

The integrated management system is designed in particular to provide improvements at the following levels:

- environmental / occupational safety

- legal certainty

- market access

- relations with authorities and with the public;

- loan and insurance terms

Moreover, the system will create the prerequisites for applying for electricity tax and eco-tax relief for the next few years – a fact which is of particular importance with regard to foundry operations. One key principle governing the new system is that its harmonization with the existing Quality Management (QM) structure must be ensured in order to benefit from synergy effects. In this context, the existing QM system process descrip- tions will likewise be represented in the form of flow diagrams for the sake of achieving improved clarity and transparency.

The system is based on the following standards:

- ISO 14 001 (environmental management)

- ISO 50 001 (energy management) and

- OHSAS 18 001 (occupational safety managemen

Furthermore, for the equipment construction activity it incorporates ISO 14062 (integration of environmental aspects into product design), as well as CE requirements.

The system will be established using standardized documents throughout the entire company. First steps towards the introduction of the new system were initiated in late 2012. As early as in the summer of 2013, it is intended to test the effectiveness of the integrated management system as part of a certification drive.