"The man of the match" in the digitisation process is Jean-Pierre Hacquin, EDP manager at the Kempten iron foundry. He is one of few who always sees things from two perspectives: as a foundry man and an IT specialist. "There was always a follow-up project to use and develop the experience of previous projects, but also to balance out weaknesses of the last project," explains Hacquin. It turned out that at the beginning of the digitisation phase in the Kempten iron foundry, generally too little data had been collected. One of Hacquin's permanent projects is data processing.

"We had to retool machines, set up new IT structures and motivate employees. It was a long road, with many unforeseen problems that had to be managed. Everyone had to pull together," says Hacquin, who developed an app with the IPI and his team in the past, with information on the respective casting for the employees. However, the first version of the app was used less than expected. But Hacquin remains positive: "We continue to develop consistently, we keep entering new test phases, we keep trying out new things to see what works and what not. And it's always about taking the right people on board for a project."

Win-win situation for university and iron foundry

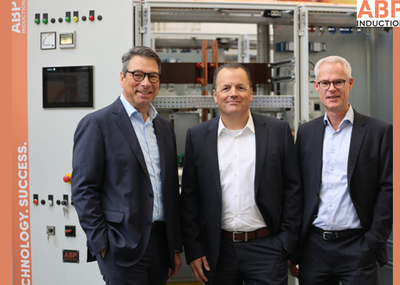

The cooperation with the university brings numerous advantages, as EDP manager Hacquin states. "Professor Hartmann supports us with the right people, so we get positive results." And from the Kempten University of Applied Sciences, too, the cooperation is seen as a win-win situation. "We need to have the right partners from the beginning to start a project and to make sure it keeps going. And with the Kempten iron foundry, that is the case," also emphasises Prof. Dr.-Ing. Frieder Heieck from the IPI.

Foundry manager Michael Windl also approves of the numerous advantages resulting from the cooperation, such as a cost saving of 5.4 per cent with the same production input: "I confirm: It's always a cooperation. You try to do everything together as a team." Yet, the secret of success of a successful cooperation lies not only in the togetherness, but also depends on the external framework conditions. "What it needs is a common frame in which one can operate well. It is crucial that financial scope and time are given and that partial successes are celebrated," says Windl.

What does digitalisation and AI mean regarding the foundry?

Artificial intelligence and digitalisation are related. The question is: what does digitalisation mean for the foundry? "What we want is to create an information base to facilitate work in the company, to become more efficient and effective, and ultimately to contribute to securing the future of the company. First of all, this is not about AI at all. Of course, we have AI projects when it comes to analysing and optimising complex process relationships. But first of all, the basis is data. In a foundry, an incredible number of processes run simultaneously, are extremely interconnected and often influence each other. And a sufficient data basis enables knowledge creation and forms the foundation for AI-supported operational decisions," explains Hartmann. This opinion is also shared by Managing Director Mr Hübner, who emphasises the economic efficiency of a project in this context. " Data collection has to pay off. Otherwise we don't get on the winning road and there are many trouble spots."

According to Hacquin, a consistent data structure now exists in the Kempten iron foundry. "A lot of data has been collected in the past. This is currently stored in a cloud, where many gigabytes of company data are already available for viewing and evaluation. This data forms the basis for the plant management and the management to make decisions," says the EDP manager.

The question is, how do we use the data?

Hacquin even goes one step further in his question: "The plants we have collect data anyway. Today, however, we are at the point where we want systems that collect data - individually for us. The basic question is: at what point in time can we collect information at all? For example, when a melting furnace is switched on, or when the crucible is changed?" Many projects fail not at the point of collecting data, but at the fundamental question of how the data can be used. The art, then, is to combine the findings of science with the experience of production. All of this is based on a common structured approach in order to work out objectives, wishes and necessities via the questioning technique. For Hacquin, the solution is to provide each department with the appropriate data. Or as Heieck sums it up: "Our goal is data networking at a high level in order to analyse meaningful correlations."

The "right" interpretation of the data by qualified personnel

Hartmann also states: "When it comes to finding the correlations - when it comes to comparing data - it is important that this is done by an IT specialist. That sounds easy to implement, but it is not so easy to find such people." The Kempten iron foundry is currently looking for the right personnel to analyse this immense variety of data "properly". Because according to Hacquin, in order to optimise a foundry, the selection process needs to be different from the one used for quality assurance or production planning, for example.

What are the advantages of digitalisation and the application of AI in the Kempten iron foundry?

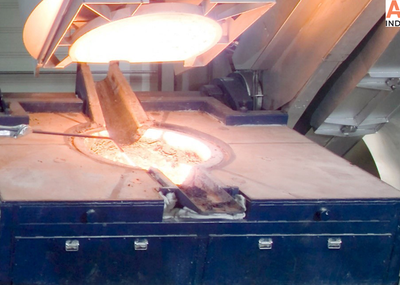

The advantage is that high costs can be saved in the foundry. This applies, for example, to the question of when the most favourable time is to replace the crucibles. If they are replaced too early, this causes a large cost block in the new acquisition. If they are replaced too late, however, there is a risk of them cracking and melt escaping. AI can therefore be used to predict when the crucibles need to be replaced, taking into account the diverse and constantly changing process-related influencing variables. And today the Kempten foundry is at the point of being able to predict this precisely. According to Windl, these results provide completely new inputs. "Crucible wear has a big influence on energy consumption, but you don't even see that in the data without special analyses," says Windl. The task of AI is to recognise complex interdependencies in the data and make them usable for decisions about optimised process control.

With regard to the melting facility, Kempten's equipment supplier ABP Induction had solutions available for comprehensive data acquisition, but no specialised personnel to carry out company-specific data analyses. Florian Huber, research assistant at the Kempten University of Applied Sciences, has access to the entire data structure of the Kempten iron foundry, including all data from the energy management system. This makes the correlations between process management and energy consumption immediately visible and usable for appropriate optimisation measures.

Today, foundry plant manufacturers consciously advertise that their machines and plants provide a multitude of measurement data, whether melting plant or sand mixer. "But machines are first of all only data sources. The fact that they offer an AI that links data and offers solution suggestions does not exist in this way," says Hartmann. With the energy management system, energy consumption data is collected and statistically processed. But afterward, competences are needed that can precisely experiment with these data and intelligently link them with other production or process data. And this is exactly where AI process models come into play. The benefits and applicability of these models depend on the direct interaction of the competences involved, which in this case are the foundry itself, the furnace manufacturer ABP and the AI competence of the IPI. It is this cooperation of all the necessary experience and competences that forms the basis for the success of digitisation projects," says Hartmann.

How do you prepare employees for digitalisation?

Another issue concerns the insecurity of foundry employees when it comes to digitalisation. Because the mentality of foundry men is still more traditional. "All our casting reports are written by hand and then digitised in AV. There was an attempt to bring all casting reports into an app so that every employee could get information about what was produced the previous day, for example. But the project was stopped because the employees were not yet ready for this," says Kraus.

When it comes to digitalisation, however, a company depends on the support of its employees. But there is often a lack of transparency, which only reinforces employees' fears of "being replaced by the machine one day". Alexander Kraus, who is responsible for work preparation at the Kempten iron foundry, states. "Many of our employees - especially the older generation - cannot imagine what digitalisation means. They find it difficult to imagine that a machine should do the same as they do themselves. Yet it's not about replacing people with a machine at all, but supporting them in their work."

Changes in education and training in the foundry industry

A central issue for foundries is the adaptation of training and further education of their employees with regard to digitalisation. According to Heieck, this is precisely where engineering training should start. "Basic IT skills, e.g. in programming languages that are often used in web applications, in handling data and in machine learning (ML), should be an immediate part of engineering education. Engineers of tomorrow need to learn this," states Heieck. Finally, everyone in the discussion agrees that it is a matter of skilled personnel being able to see the big picture and to perceive the production process as a whole. This means that the interfaces between staff and process play a special role, which must be developed in the form of assistance systems that work and can be operated simply and effectively. "At the Institute, we are currently discussing how we can tackle this. We have to develop support tools for the workplaces in a digitalised production environment that are adapted to the respective employee task," states Hartmann.

Where does the journey lead? Future outlook of the Kempten iron foundry

The cooperation between the Kempten iron foundry and university will continue in the future, as all participants are highly motivated. "We want to take our future into our own hands and want to be in the premier league. We want to be better than our competitors by continuing project work, especially with the Kempten University of Applied Sciences," emphasises Roland Hübner, CEO of the Kempten iron foundry. Further primary goals are increased efficiency, stability and energy savings. The Kempten Iron Foundry also wants to create structures and a basic understanding of digitalisation and AI - step by step with time, patience and humility. In view of the serious shortage of skilled workers, the goal today is to secure the knowledge and experience within the company in such a way that it can be easily accessed by future generations of employees. Digitisation efforts at the Kempten iron foundry are always about to see the positive in joint projects and recording new successes. But the Kemptener's most important goal is to be one of the best foundries in Germany - on that point, everyone in the group agrees.