Mercedes-Benz even started to develop a luxury electric car series. The development of new energy vehicles has become an unstoppable trend. A new round of competition has begun.

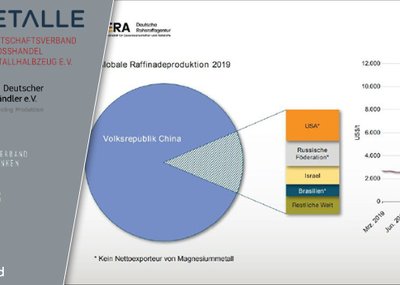

Magnesium and magnesium-alloys are recognized as one of the lightest structural metallic materials and are known as green materials with great development and application potential in the 21st century. Magnesium alloys have the advantages of light weight, high strength, good mechanical properties and heat dissipation, etc., making them the preferred material for lightweight vehicles. It is for sure that there will be more and more applications with the advent of the electric era.

Bestseller in China, Germany, and US

Long-term strategic cooperation with customers

In the international market, the promotion of new energy vehicles brought a lot of demand. Despite the impact of the pandemic, several customers in China, Germany and the United States purchased the Thixomolding machines from YIZUMI for the production of lightweight components.

In April this year, the U.S. customer completed the installation and commissioning of the machine and ran a trial production of a 1.5 kg seatback. The customer is very satisfied with the product quality. In addition, the customers in Germany and China have also achieved mass production and are pleased with the machine efficiency and product yield.

CASTWERK is a German company specialized in auto part production, producing structural parts like new energy vehicle screens. Their customers include large auto parts suppliers such as BOSCH and Continental, and end customers such as Volkswagen. In response to the market demand, the company is planning to import the third Thixomolding machine from YIZUMI this summer.

Meigaomei Nuojiang (Tongchuan) New Materials Co., Ltd. is a hi-tech enterprise specialized in the design, R&D, and production of high-strength magnesium alloy materials. They supply high-quality magnesium alloy customized products to the aerospace-, military-, automotive-, 3C-, biomedical-, high-end equipment-, and other industries. The enterprise focuses on the Thixomolding technology R&D while mass-producing magnesium alloy parts.

Besides manufacturers, R&D institutions are also important strategic partners for YIZUMI. The Center of Casting Lightweight Materials and Engineering at the University of Kassel (GTK) is a research institute which has its focus on casting technology. At present, the center teams up with YIZUMI to research the use of a multiple points hot runner system for our Thixomolding technology.

"Cooperating with GTK, YIZUMI can demonstrate our Thixomolding technology to customers in Europe and around the world. It will be our best example," said Tiejun Sui, the Product Manager of YIZUMI Thixomolding Project.

Optimize application technology

Explore new applications of magnesium alloys with customers

Based on the cooperation with customers in China, Germany, and the United States, YIZUMI has obtained many technical feedbacks to optimize existing equipment and add more features to the machine in response to the needs of customers.

This year, YIZUMI will continue to explore new applications of magnesium alloys with our customers. For example, the UN300MGII and UN1500MGII models developed by YIZUMI will provide Thixomolding technology benefits in both small-part and large-part production.

The main field of UN300MGII application will be small parts, including 3C electronics, drone components, and some small auto parts. There will be three options for the diameter of screw and barrel (small, medium and large diameter), allowing customers to choose the most appropriate specifications for their applications to ensure product quality and production yield. It employs an energy-saving servo drive system that greatly reduces energy consumption. The new design includes an optimized movement control system to improve operation efficiency, increase customer output, and bring customers better molding quality and productivity.

"The UN300MG II will offer great opportunities to our customers in the smaller component markets.” said Mr. Philipp Ochotta, Head of R&D of YIZUMI (Germany), our Lightweight and Multi-component Manufacturing Research Center. "YIZUMI Thixomolding machines combine the technologies of Germany and China, and the technology is constantly improving. We are confident that its performance fulfills international standards.”

Developed by YIZUMI headquarters and YIZUMI Germany R&D center since 2021, UN300MGII is a small-shot-weight model which has adopted Europe's cutting-edge hot runner technology and provides better filling performance and product quality. The products made by this machine feature dimensional stability, high functional integration, lightweight, and less post-machining process requirements.

“The product had made a successful debut at CHINA DIECASTING 2021 and it was great to see YIZUMI Thixomolding technology is recognized by customers. The UN300MGII machine with its great combination of appearance, operation and excellent performance is promising". Tiejun Sui said.