ConviTec used sand cooler CSK with innovative fluidised bed process

ConviTec used sand coolers are used for the economical and precise cooling and homogenisation of hot used sand in continuous operation. ConviTec used sand coolers guarantee a consistently high quality of the moistened and cooled sand, regardless of the inlet temperature of the used sand.

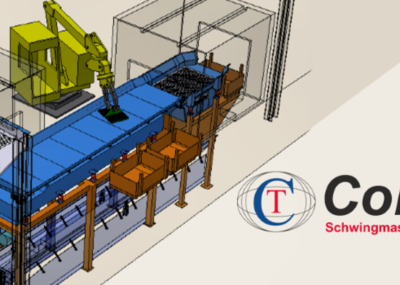

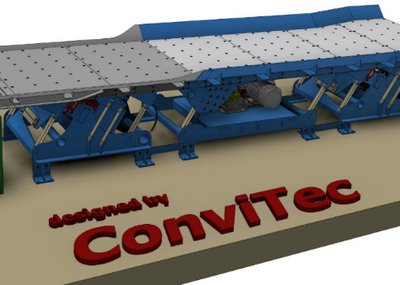

A cooler consists of an oscillating conveyor with a closed air box and an air-permeable inflow floor made of special steel. ConviTec unbalance motors or exciters serve as vibration drives. Frequency converters enable the optimum conveying speed of the used sand to be set. A supply air fan generates the necessary cooling air. A stationary hood with integrated humidification device and sensors for temperature and humidity complete the cooler. The measurement technology is easily accessible outside the cooler. With the single-stage control of the multi-stage water dosing, setpoint deviations of +/- 0.3% are achieved.

Increasingly, higher accuracies are in demand. To meet these requirements, a two-stage control of the multi-stage water metering is necessary. The first control loop is activated depending on the moisture measurement at the cooler inlet. The second control loop defines the control measurement and humidity correction at the cooler outlet. In this way, setpoint deviations of +/- 0.1 to 0.2 % are achieved. The recording of the states of used sand (temperature and humidity), water quantity and air are the prerequisites for this.

An intelligent PLC-based control system in conjunction with a touchscreen as a moisture measurement and control system ensures consistent sand quality and supports the operator, especially at the start of production. Data logging and interfaces, such as Ethernet or ProfiNet, are available for communication with higher-level systems.

The ConviTec used sand coolers with the innovative fluidised bed process produce a consistent sand bed and thus a consistently high sand quality with low fluctuation and optimum moulding properties through the combination of linear oscillating movement and air flow under different operating conditions.

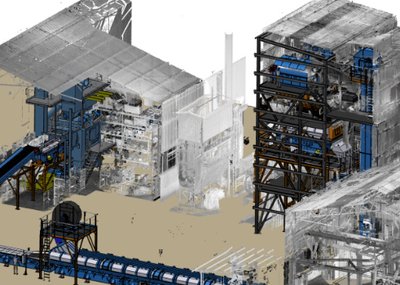

The installation of a ConviTec used sand cooler in a sand processing plant has the following advantages:

- Very good homogenisation of the sand due to intensive mixing at low bed depth,

- Shortening of mixing times due to precisely adjustable moisture and temperature of the used sand, early swelling possible,

- Improved sand quality and workability of the moulding sand,

- No mechanical stress on the sand due to mixing tools, i.e. no abrasion on the sand grains,

- Reduction of the sand circulation quantity or saving of used sand bunker volume, cooled used sand is immediately available,

- Considerable reduction of new sand addition and binder due to gentle suction,

- Extremely low wear due to air flow between inflow floor and sand bed,

- High operational safety, robust design, reliable, low maintenance, high availability and long service life,

- Start-up under full load possible without problems,

- High economic efficiency and low operating costs due to low energy consumption of the drive units.

Compared to mixer coolers, ConviTec used sand coolers with the innovative fluidised bed process provide cooling of the used sand to below 45°C. Compared to mixer cooler systems, which not only have a higher fan power but especially a very high electrical power installed for the mixer drive, ConviTec used sand coolers only require 30% of the electrical power.