also availbe in <link _top external-link-new-window>

Mössner August GmbH - Foundry Technology

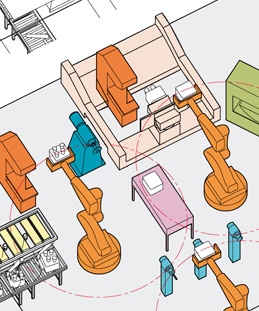

Mössner designs and manufactures completely automated casting finishing cells with all necessary casting cleaning processes: Casting decoring, casting handling, casting transfer, gate and riser cut off, design and manufacturing of part specific tooling (grippers, fixtures, pallets…), casting cleaning and deburring, separating and removal of returns all the way to the handling of inspected castings. The processing cell can be of a fully sound enclosed compact type or transfer line design.

Mössner designs and manufactures completely automated casting finishing cells with all necessary casting cleaning processes: Casting decoring, casting handling, casting transfer, gate and riser cut off, design and manufacturing of part specific tooling (grippers, fixtures, pallets…), casting cleaning and deburring, separating and removal of returns all the way to the handling of inspected castings. The processing cell can be of a fully sound enclosed compact type or transfer line design.

You can find further information about the different areas here:

Degating For cutting of risers and runners Mössner offers automatic and semi-automatic bandsaws. The semi-automatic bandsaw VB 802 with numeric control offers many different finishing options.

For cutting of risers and runners Mössner offers automatic and semi-automatic bandsaws. The semi-automatic bandsaw VB 802 with numeric control offers many different finishing options.

With the fully automatic version the robot loads the casting onto a fixture with two clamping positions. Then the risers are cut off with a bandsaw, e.g the HB801 with two CNC-axis. All operations are fully automatic and different types of castings can be processed on one saw.

Robot grippers and fixtures are adapted for the processing of up to 4 different cylinder heads in a complete mix.

Decoring

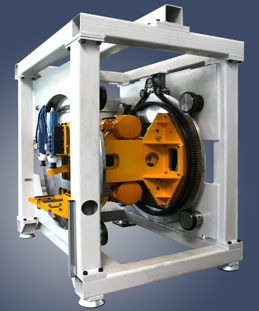

The decore unit provides a casting adaptable environment, a thorough decoring result and features automatic part recognition processing a mix of castings. The newly developed, high feature decore unit is robotically loaded and unloaded. The sand core and adhering sand are broken down by electrical hydraulic hammering and then completely removed through vibrating and rotating action.

The decore unit provides a casting adaptable environment, a thorough decoring result and features automatic part recognition processing a mix of castings. The newly developed, high feature decore unit is robotically loaded and unloaded. The sand core and adhering sand are broken down by electrical hydraulic hammering and then completely removed through vibrating and rotating action.

The casting specific decoring operating parameters are adjustable and programmable. The decoring cycle time is casting specific, and for example, the double loading of two cylinder heads achieves an approximate 46 second cycle.

A sound enclosure (sound emission: <80db(A)) with automatic operated loading / unloading door encloses the decore unit. The operation can be described as breaking the castings internal sand core with pneumatic operated hammers followed or parallel by electrical vibration action grinding down the loose sand and then removing the loosened sand through casting roll over.

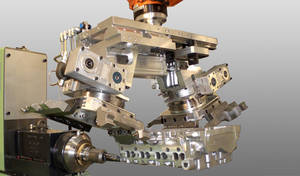

Deburring The easily programmable 6 axes robot handling the casting makes a deflashing and deburring operation possible by manipulating and feeding the casting through different work stations:

The easily programmable 6 axes robot handling the casting makes a deflashing and deburring operation possible by manipulating and feeding the casting through different work stations:

- Rough milling with face mill

- Fine deburring, for example parting line with high frequency milling spindle

- Deflashing, cleaning and working on holes and openings using quick change multi drilling stations

- Removal of burrs and flashes with a trim press

Automatic casting finishing quality check is possible with the integration of measurement stations, vision systems, casting internal check through vision endoscope or X-ray machines.

The Deburring Center is suitable for the automatic deburring and the removal of secondary flashes. The machines provide a high degree of flexibility, comparable to that of manual processing. Within a short time, new machining processes can be defined and started. Handling is simple. The compact and space-saving design facilitates installation even in very confined spaces. The Deburring Center is delivered as a complete unit and can be put into operation immediately.

Engineering

From the raw casting to the finished workpiece.

We design the complete concept for:

- preprocessing, inclusive discharging out of the casting mould,

- decoring,

- deflashing,

- transportation and

- handling.

<link _top external-link-new-window>Click here for more Information and Contact to Mössner August GmbH + Co. KG in our Suppliers Profile

<//font>