Key component of a MorganMMS global support strategy

The recently established Global Technology Team (Tech Team) from Morgan Molten Metal Systems (MorganMMS) is already having a very positive impact on crucible performance and foundry operations.

Under a new strategy of centralizing innovation and continuous improvement, the “Tech Team” has been positioned as MorganMMS’s center of technical expertise for issues involving product performance, application variables and other process related controls. The primary goal of the Tech Team is to work towards the continuous development of new and improved products applicable to customers, markets and industries. When customers have unique requests in terms of product improvement or process changes, the Tech Team will be at the forefront in meeting their needs and providing cost-effective solutions. The Tech Team will not only be a research center, but also a troubleshooting and problem solver for MorganMMS’s customers.

“This is an entirely new concept within our industry,” says Mirco Pavoni, Technology Director, MorganMMS. “The kind of on-going dialogue between the Tech Team, our customers and the marketplace in general will enable MorganMMS to stay ahead of anticipated problems, while generating improved products that help foundries stay competitive and be more productive.”

New Ideas for New Solutions

A little more than one year ago, the Tech Team was set up by a group of experts from MorganMMS with a mission of leading the innovation process and providing technical support to the rest of the organization. The team’s initial objective was to create a process to manage technology projects and create a pipeline to collect all new ideas and trends from the crucible marketplace, including from MorganMMS’s employees, its customers and the market in general.

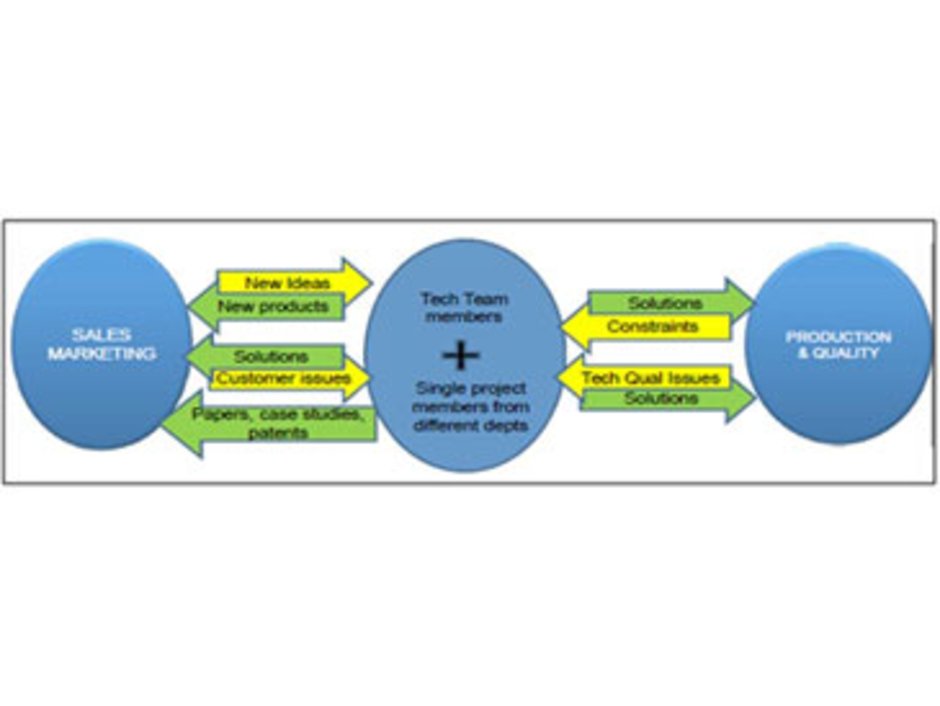

The resulting technology process focuses on realistic objectives: solving technical issues, developing new and improved products and transforming ideas into reality. To accomplish this, the Tech Team’s responsibilities go hand in hand with the on-going MorganMMS global re-organization which calls for the close cooperation among the company’s Cross-Functional Teams and other company departments. The process allows for sharing input and feedback on a continuous basis in order to remain on the cutting edge of industry needs and problem solving.

While a number of Tech Team projects have already proven themselves in foundry operations, the team has also developed new and improved products for new markets. A new clay graphite transfer liner, for example, has generated an unmatched level of mechanical strength consistency, less erosion, improved performance and longer service life for casting operations primarily for the manufacture of ductile iron piping. Regarding crucibles specifically, the Tech Team has developed important products for specific markets, including gold refining, melting fusion salt, glass melting and continuous casting. These are good examples of how the Cross-Functional Teams working on Tech Team projects have achieved superior product quality goals through team interaction.

On another project which has led directly to improved product performance and smoother customer operations, the Tech Team developed a one piece, silicon carbide degassing rotor and shaft to help remove dissolved hydrogen and unwanted particles in the melting or holding process. The new degassing rotor has a high resistance to in-service wear and has excellent anti oxidation properties, providing a cost effective consumable for use in foundry degassing processes. The rotor is available in a range of sizes to suit customer applications.

###COMPANY_LINK### <link record:tx_browserdirectory_directory:4925 internal-link>![]() Morgan Molten Metal Systems

Morgan Molten Metal Systems