3D printing materials are one of the most rapidly growing segments of the 3D printing industry, and we have more high-tech and advanced material options than ever before. But usable 3D printable material options are always going to be limited to the technology of the 3D printer being used. There are currently several high-strength and lightweight materials available, however truly advanced composites are currently beyond the capabilities of modern 3D printing. Because many composites require the multiple materials to be arranged in very specific micro-scale structures while being formed, current technology is simply incapable of using them.

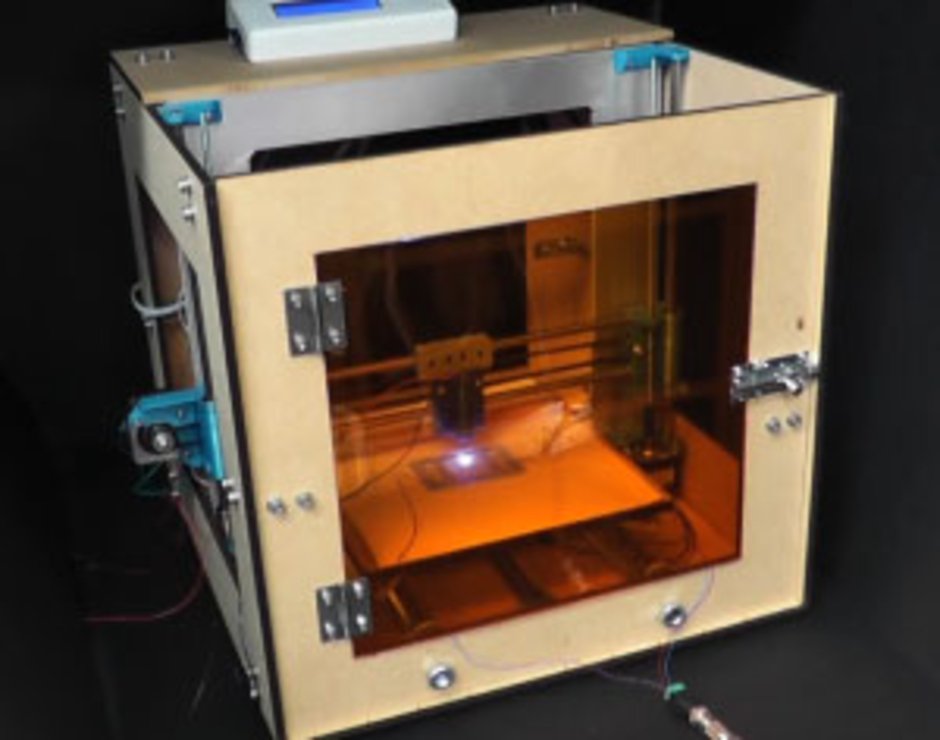

But a team of engineers from the University of Bristol — comprising Thomas M. Llewellyn-Jones, Bruce W. Drinkwater and Richard S. Trask — have developed a new hybrid type of 3D printing that can both assemble and print with composite materials using a combination of desktop 3D printer technology, light-curable resins and ultrasonic waves. This new process can allow super strong and lightweight composites like the variety used to produce tennis rackets, golf clubs, professional bicycles or even airplane parts to be used with additive manufacturing technology. Needless to say these new material options will offer entire new industries the ability to incorporate 3D printing into their manufacturing workflow. And the best part is that for the most part the process was made using existing 3D printing technology.

Composite materials are made by combining micro-structures of glass or carbon fibers with a plastic material. The carefully arranged fibers lock together and give the new material its strength and durability, while the plastic ensures that the resulting material will be lightweight. Currently, composite materials are manufactured as thin sheets that are then layered and cut into the desired shape and thickness. The problem with using this as a 3D printing material is the small fibers in the composite materials. In order to produce the desired strength the fibers need to be aligned in a very precise structure, which is currently not possible to reproduce using a 3D printer.

However the Bristol researchers have discovered a process that exposes a light-cured resin material combined with millions of micro-scale glass fibers to ultrasonic fields produced by a pair of transducers. When the ultrasonic waves are directed at the liquid material at specific frequencies it creates a forcefield that will organize the glass fibers into the desired structure. The glass structures act as material reinforcement, similar to the way that rebar is used to strengthen concrete structures like building foundations or bridges. Once the structures are complete the resin material will then be hardened using a very tightly focused laser beam. The result is a composite material that has the same properties as those made with traditional composite manufacturing methods.

“Our work has shown the first example of 3D printing with real-time control over the distribution of an internal microstructure and it demonstrates the potential to produce rapid prototypes with complex microstructural arrangements. This orientation control gives us the ability to produce printed parts with tailored material properties, all without compromising the printing,” said Bruce Drinkwater, UofB research team member and Professor of Ultrasonics in the Department of Mechanical Engineering.

Aside from the added benefit of durability and strength, this new composite material 3D printing process also offers the ability to make entirely new composite patterns that can’t be manufactured using traditional methods. The ultrasonic wave pattern can easily be slightly altered or adjusted to steer and position the glass fibers during the 3D printing process, giving a single material the ability to be 3D printed into a limitless number of composite materials with a wide range of uses and applications. This is primarily because standard manufacturing allows only for two dimensional structures to be assembled and then layered on top of other layers of two-dimensional structures. However 3D printing offers the option of creating highly complex three-dimensional structures never before possible.

The ultrasonic alignment process will give product designers and engineers entirely new options for creating smart materials that are capable of automatically performing complex actions like self-repairing damage. Researchers are already looking into embedding networks of tubes of uncured resin material inside of an object that when ruptured will simply bleed out and repair the structure of the object. These tubes could easily be placed and constructed using controlled ultrasound waves. Structures can also be made that will absorb, store and transmit electricity or data, which would remove the need to assemble simple electronics or data transmission devices.

It is still quite early in the development process of this new ultrasonic 3D printing technology, but as we’ve seen time and time again, this industry moves incredibly fast. It isn’t hard to imagine that we could be seeing 3D printers with this type of technology hit the market within the next few years. You can read the entire paper compiling the research from the University of Bristol team called “3D Printed Components with Ultrasonically Arranged Microscale Structure” here. Discuss your thoughts on this new process in the Ultrasonic 3D Printing forum over at 3DPB.com.

Source: 3Dprint.com

×