Anhui Xinke New Materials Stock Co. Ltd., the Chinese copper strip manufacturer based in Wuhu City, Anhui province, had signed a contract for the supply of two induction furnace systems with INDUGA in October 2012. As part of a drive to expand production capacity, the equipment is intended to provide copper-iron alloy stock for the production of leadframe strip of high electrical conductivity.

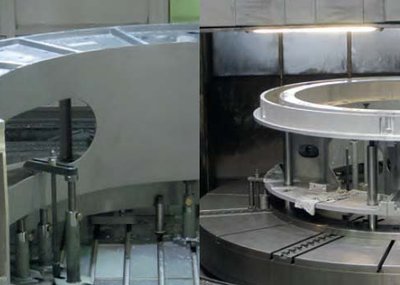

For melting down copper cathodes and return scrap, a 10-tonne medium-frequency coreless furnace with a rated power of 3,000 kW at 250 Hz is to be provided by OTTO JUNKER GmbH. The system can achieve a maximum melting rate of 7.5 tonnes/hour.

The furnace will be equipped with a stepless tilting feature allowing the vessel to be tipped backwards by up to 20º to facilitate de-slagging.

From the melting furnace the liquid metal will be transferred directly to a mobile sidewell-type pouring furnace equipped with a 300 kW coreless inductor. Both furnace systems are to be fitted with power converter and switchgear equipment based on IGBT technology, apart from receiving the most advanced process control technology. Our scope of delivery will likewise comprise the water recooling systems as well as the charging equipment for the melting furnace.

Delivery of these furnace installations is slated for October 2013. The customer aims to commission the production line in April 2014.

Partner

Topic Continuous casting

Topic Melting Shop

Foundry Corporate News

OTTO JUNKER: Induction furnaces for melting and pouring

Reading time: min

[23]