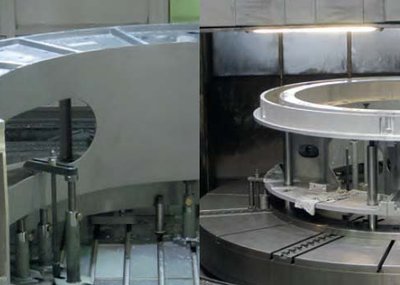

Early this year Ludwig Frischhut GmbH & Co. KG placed an order with OTTO JUNKER for delivery, installation and commissioning of two totally independent medium- frequency melting furnaces using MonoMelt technology. The new furnaces are meant to replace the existing mainsfrequency coreless induction furnaces. The scope of supply of the two complete melting units essentially comprises:

- Coreless 5-tonne furnace with extraction hood and weigher

- 3,200 kW IGBT frequency converter system of 12-pulse configuration with high-voltage transformer

- Multi-frequency technology for 125/250 Hz

- Water recooler with air-to-water cooler

- Charging machine

- M2F Touch Control System for visualization and operation

The decision was made for two independent furnace plants because this redundancy makes it possible to run both furnaces simultaneously without any restrictions. Moreover, stoppage of any one furnace would not stop the whole melting operation. Due to the weakness of the high-voltage supply mains both transformers were designed to minimise the system load (transformer phase shifting). The multi-frequency technology is provided for optimum carburizing or alloying of the melt by switching the frequency from 250 to 125 Hz. This intensifies bath movement and thus accelerates stir-down.

Compared to the mains-frequency furnaces the new medium-frequency melting units have a much higher melt output and can be started-up without a heel - with higher efficiency and thus lower energy consumption.

Each of the two medium-frequency melting furnaces is designed for a maximum melting rate of 5.9 tonnes/h with an energy input of 500 kWh/t related to 1,450 °C. As the two furnaces are independent, delivery and installation was scheduled in two steps: The first unit was to be delivered in week 31, the second in week 40. For the first unit, user training, supervision and complete instal- lation have meanwhile been completed on schedule. In very close cooperation with the professional staff of Ludwig Frischhut GmbH & Co. the furnace was handed over to the foundry following successful commissioning in early September. In agreement with the customer the second furnace plant including charging machine was presented at the Furnace Convention held in Lammersdorf on the occasion of the 90th anniversary of OTTO JUNKER GmbH. Despite this interim presen-tation the agreed delivery date in week 40 was not at risk and has meanwhile been met. This project was and still is characterized by the excellent support by the custom r and a very good working atmosphere so that any arising problems were solved quickly and in a target-orientated manner.

Meanwhile, the second plant has been commissioned successfully.