Traditional castables offer excellent performance, but they are often criticised for the need to have lengthy, controlled installation and drying schedules. This impacts directly on the foundry by reducing equipment flexibility, available production time and increased energy consumption.

By listening and understanding our customer needs Calderys developed the QD NCC concept.

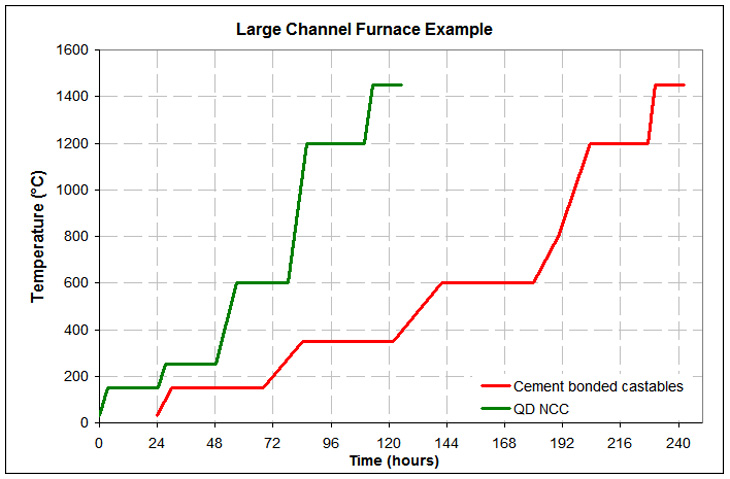

This NEW range of castables utilise a novel technology enabling immediate heating after former removal (no curing) and at rates up to 100oc/hr. The net result allows complete heating of the castable in less than 50% of the time. This factor saves energy, improves equipment flexibility and reclaims valuable available production time for the foundry. Additionally heating can be completed in a safer way with low risk of vapour damage even with low velocity burners.

QD NCC's are available in many raw material bases meaning use in virtually all metal grades (iron, steels, aluminium...etc.) as well as thermal (non-metal contact) applications, and virtually all equipment seen in foundry where traditional castables are used such as ladles, cupola, holding and pouring furnaces...etc

Performance results seen have been equal or better than traditional castables and can demonstrate improved thermal shock resistance in many applications giving increased reliability potential.

Typical Heating Example

See the CALDERYS Team at GIFA in Hall 10 Stand A20 and discuss

Your Full Savings Potential for FULL VALUE IN USE