SCANIA is a world-leading Swedish provider of transport solutions, including trucks and buses for heavy transport applications combined with an extensive product-related service offering; it is investing about SEK 1.5 billion in a new foundry in Södertälje, Sweden in order to triple production capacity and achieve a 50 percent reduction in energy consumption compared to the technology and methods used in the current foundry.

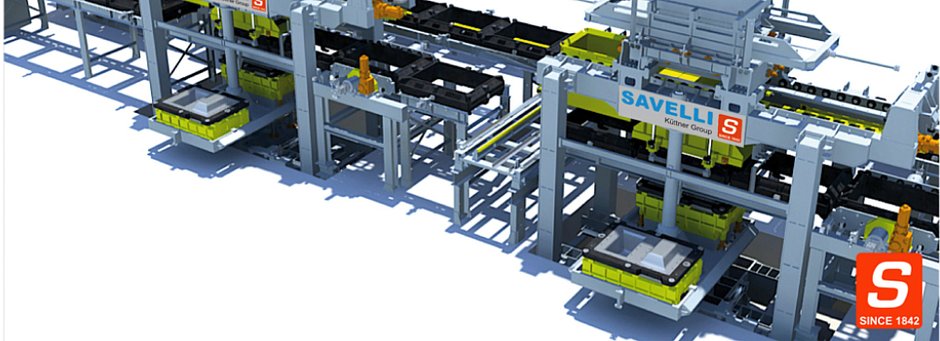

Through more efficient materials handling and recycling, a sharp reduction will also be achieved in the transport need per manufactured unit. The foundry will be operated using electricity produced from renewable energy sources... As the first step, SCANIA selected KÜTTNER SAVELLI for the supply of a complete new high performance automatic flask molding line to produce motor blocks and heads.

The engineering team paid special attention to a detailed process comparison for the first package to be awarded. In addition to meeting the stringent quality requirements for mold quality and its repeatability, special attention was paid to the overall energy consumption.

Here, the mold’s compaction process Formimpress® offered by KÜTTNER SAVELLI was particularly successful because it requires no compressed air for compaction and has a minimized hydraulic connection capacity. Also, all possibilities of feedback from kinetic energies are used. In order to significantly improve the resource efficiency of the foundry, SCANIA has taken great care in examining all the details involved separating the material flows and decided to lift the castings package up and out of the mold in order to separate the handling of the core and green sand flow. This lifting up and out concept enables both material streams to be prepared in the best possible way and reclaimed with a low energy input. For the core sand one expects a recycling rate of 70% which has a large influence on the environmental sustainability of the entire production taking under consideration the long supply ways for new sand. KÜTTNER SAVELLI is particularly happy about this success at SCANIA and has already stepped into the detail planning of the new system. The engineering team is supported by GEMCO Engineers B.V., Eindhoven (The Netherlands).