Starting shot for in-house production

ebalta improved its quality for mould- and modelmaking

At the beginning of this year ebalta Kunststoff GmbH switched completely to in-house production of tooling boards with density d>1 kg/l. The new product range as well as improved service offer more options for mould- and modelmaking.

ebalta Manufacturing plant |

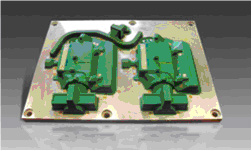

This year ebalta started with its “ebaboard PW 920 new” for model making, core boxes, pattern plates and jigs. Compared to the former long-time proven green boards “ebaboard PW 920 new” shows much better abrasion and impact strength as well as flexural strength.

Moreover we were able to reduce the coefficient of linear expansion by about 22 % which leads to much better machinability and more dimensional stability.

The new board does not contain any abrasive fillers and can be milled very well without any formation of dust. Thus you get a perfect surface and your models and moulds distinguish by an excellent quality.

For optimum machining new milling parameter and recommendations for seven different types of milling cutters are available.

|

Our new service conception also includes an additional range of ebablock® material, means we can offer our total ebaboard material density d>1 kg/l in individual dimensions, e.g. according to your pattern plates. Last but not least we can supply you a complete range of the corresponding coloured adhesives, repair compounds as well as casting compounds for each board and block product, to which the material characteristics of the accessories relate too.

The product range with material density d>1 also include ebaboard LX-1, ebaboard 1200, ebaboard 140 or ebaboard W. All of them are available as ebablock® as well.

Improved quality: ebaboard PW 920 new |

<link _top external-link-new-window>Click here for more Information and Contact to ebalta Kunststoff GmbH in our Suppliers Profile