Stefanie Bischof, Head of Melting Operations at

Prejudice is something that Stefanie Bischof has never allowed to daunt herself. Through dedication and expertise, she has demonstrated her capability to run the male-dominated melting operation at ERGOCAST Guss to everyone around. And her track record is impressive, indeed. One cornerstone of the foundry's success is its partnering cooperation with Otto Junker. We talked to the 38-year-old foundry manager about the acceptance she has gained in a profession controlled mainly by men, and about the development of the cooperation with OTTO JUNKER.

When you joined the melting operation of ERGOCAST Guss, you did so as a lateral entrant – a novice taking a leap, as it were. Did you hesitate at first?

STEFANIE BISCHOF: Yes, I hesitated initially because I was unfamiliar with foundry technology. I thought I should start out by gaining some practical knowledge on how the equipment worked. So I spent a few months melting steel at first when I came to ERGOCAST Guss. It forced me to prove myself, to cope on my own. After ten months I took on the post of Head of Melting Operations. During all of this time, I acquired the theoretical know-how by studying foundry technology on the side at VDG.

On the production floor, almost all workers are men. Were you accepted as a supervisor?

STEFANIE BISCHOF: At the very start I was looked upon as "li'l Steffi" by some. But this changed quickly. I took a few courageous decisions in plant breakdown situations, the kind that proved just right in hindsight. So acceptance eventually came to me. Today I feel that the melting shop is just the place for me to be.

Has OTTO JUNKER's service and equipment contributed to your success?

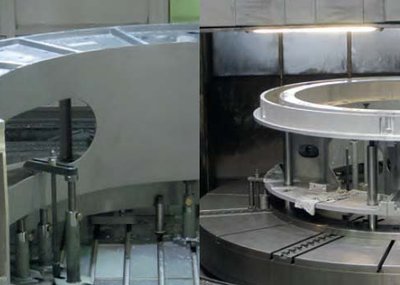

STEFANIE BISCHOF: Oh yes, definitely. Over the past 9 years we have been integrating OTTO JUNKER equipment into our production process repeatedly – for example, a melting system comprising two medium-frequency coreless induction furnaces designed for 8,000 kg / 6,000 kW and working in a Duocontrol configuration. Instead of melting 12 tonnes in 6 hours as before, we now obtain 8 tonnes in only 1 hour. This makes us more flexible and better equipped to handle customer orders at short notice. We have been able to boost our competitiveness. Since 2011 we have been using OTTO JUNKER's energy-saving coils, which cut our power needs. This is an investment that has paid off for our company. As for our pouring furnace, we're benefiting from two OTTO JUNKER innovations: the stopper control system operated by a linear actuator and the melt inoculation system. Both operate very precisely and have helped us to improve quality.

How has the cooperation between ERGOCAST Guss and OTTO JUNKER evolved?

STEFANIE BISCHOF: It has become more partnership-driven and is characterized by good faith. Our relationship is based on reciprocity, really. OTTO JUNKER grants us favourable payment terms on innovative solutions. Thus, we made the final payment on the stopper control system only after it had passed all trials. On the other hand, OTTO JUNKER can test new equipment in a practical foundry environment. These are reference systems for OTTO JUNKER. So when OTTO JUNKER asks us if we would be interested in a new development we tend to be very approachable.

Which challenges lie ahead of you?

STEFANIE BISCHOF: The foundry industry is undergoing a difficult transition phase. We too must get better all the time. For example, the quality of materials needs to be further optimized. Moreover, we have to become more efficient. The recovery of waste heat, for instance, should be improved. OTTO JUNKER will be able to help us with that. No doubt, OTTO JUNKER remains an important partner as we brace for future tasks.

ERGOCAST Guss – products are in worldwide demand

ERGOCAST Guss of Jünkerath/Germany produces castings, e.g., for gas and steam turbines, hydraulic equipment, transmission systems, commercial vehicles, plastic injection moulding machines and compressors. With a workforce of around 210 employees, the company generates € 33 million in annual sales. Its export rate is 35 to 40 %, with key markets including the U.S., Austria, Slovakia, France, Italy, Switzerland and Iran.

ERGOCAST, and her “lads”:

Her heart is always in it

Her initial career goal was to become a commercial clerk. But once Stefanie Bischof had completed her vocational training she followed another path, having decided to go for a degree in industrial engineering instead. Upon graduation, she wanted a job that would enable her to see the specific results of her work while offering the opportunity to shape and change things. Consistent with this plan she served as project engineer in a dairy factory for five years. In 2008, the 38-year-old native of Rommersheim joined ERGOCAST Guss where she has been working as Head of the Melting Operation for several years now. Through diligence and determination, she acquired the special practical and theoretical knowledge required in this special field. Her employees and supervisors appreciate her commitment, target orientation, open-mindedness and team spirit. At the time of this interview, Stefanie Bischof was about to go on maternity leave. She aims to return to the melting shop as soon as possible once her child is born. resence on site is very important, the 38-year-old manager emphasizes, and this is why her intention is to work on site for up to four hours a day. In the remaining time she will maintain close links with ERGOCAST Guss from home. No doubt, the melting shop and her crew have grown close to Stefanie Bischof's heart.