Instead of using a mill to fabricate aluminum into the parts used in railway systems, Wabtec Corp. will be using a $2.5 million 3D printer that’s among the largest in the world at its new 11,000-square-foot facility in Findlay. The company is the successor of Westinghouse Air Brake Corp. Founded in 1869 in Pittsburgh by George Westinghouse, the company pioneered the railroad air brake. Today, Wabtec is headquartered on the North Shore and has operations in Wilmerding. More than 150 years later, it opened its facility Tuesday at Neighborhood 91, as the anchor tenant of Pittsburgh International Airport’s Innovation Campus.

Neighborhood 91 was so named as a riff on Pittsburgh’s having 90 neighborhoods — and this development is the 91st. The founders include Allegheny County Airport Authority CEO Christina Cassotis, county Executive Rich Fitzgerald, the University of Pittsburgh and others. It’s billed as a hub for the burgeoning additive manufacturing industry, which uses materials such as powdered aluminum, argon, helium and neon, lasers and a computer to make things, layer-by-layer, using a 3D printer. Don’t picture the new building as a mill. It’s a large, brightly lit room with a big metal box inside of it. That box is the SLM Solutions 800 selective laser melting machine, a $2.5 million 3D printer that looks like something from the television cartoon “The Jetsons.”

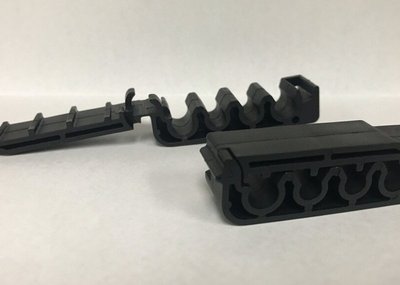

Computer-guided lasers make slight whirring sounds as they super-heat powdered aluminum layer-by-layer into whatever it’s programmed to produce. Small items with a simple design can take hours, but something like an engine control chassis the size of a small cardboard box takes eight days to make, according to Philip Moslener, Wabtec’s corporate vice president for advanced technology. It sounds like a long time for one part, but processing an order of the parts using traditional manufacturing can take eight months, Moslener said.

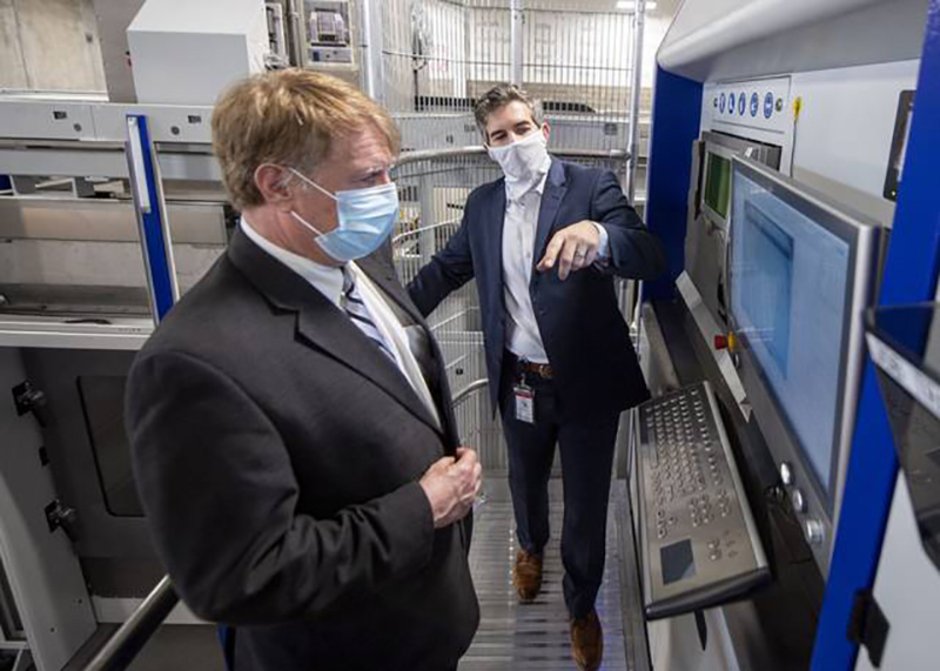

The printer takes up only part of the room, as Wabtec eyes further expansion, Moslener said. The process requires only three employees, which also increases efficiency. There are 10 similar 3D printers in the world, Moslener said. An open house held Tuesday showed off the machine to elected officials and others in the region who have partnered to create Neighborhood 91.

Announced in 2019, the center also has Arencibia, a Lehigh County-based gas recycling firm, as a tenant. Several others are expected to follow soon, Cassotis said.

“Everything you need for additive is within a two-hour drive,” Cassotis said, noting the technology programs at Pitt and Carnegie Mellon University and other plans for an environmentally friendly industrial park at Hazelwood Green. Neighborhood 91 is part of the 195-acre Pittsburgh Airport Innovation Campus in Findlay and Moon. Developing it was an idea of how the airport can best be a “strategic landlord,” Cassotis said.

Wabtec has always been a forward-thinking company, Fitzgerald said.

"When you hear words like printing parts, it doesn’t compute,” he said.

He and other officials got to see how it’s done during the tour.

“This is going to be a busy neighborhood in the years to come … as we become a real hub of additive manufacturing in the future,” Fitzgerald said.

Source: www.triblive.com