As part of the Hybit (Hydrogen for Bremen’s industrial transformation) project, ArcelorMittal Bremen, swb AG and EWE AG have received a subsidy of more than €10 million from the state of Bremen for the construction of an electrolysis plant. The funding corresponds to about half of the total investment budget.

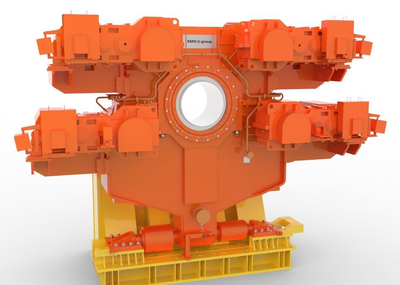

The project includes the construction of a 12 MW electrolysis plant that will produce green hydrogen with renewable energy. The electrolysis capacity is to be gradually scaled up to up to 300 MW later.

The overall demand for climate-neutral steel production in Bremen is ultimately to be met by expanding the pipeline infrastructure.

We are moving forward on the path of decarbonization in Bremen. The construction of the electrolysis plant marks the starting point for the use of green hydrogen in Bremen steel production and is an important component of transformation. We will use the first hydrogen in the existing plants, in the next stage the use of new production technologies will follow so that we can produce completely climate-neutral steel in Bremen by the mid-1930s. This will require a further expansion of hydrogen capacity.

—Reiner Blaschek, CEO ArcelorMittal Flachstahl Germany and responsible for the plants in Bremen and Eisenhüttenstadt

ArcelorMittal Flachstahl Deutschland intends to replace two blast furnaces in Bremen and Eisenhüttenstadt in the first phase of decarbonization and thus replace the technology for the production of 3.6 million tons of steel with a process with direct reduction plant and subsequent electric arc furnace.

The complete conversion of this production to green hydrogen will lead to savings of more than five million tons of CO2 per year. ArcelorMittal has submitted further applications for funding under the IPCEI program for large-scale hydrogen projects.

swb and EWE are initially building the electrolysis plant with an output of 12 MW in the joint company Wasserstoff Bremen GmbH at the Bremen-Mittelsbüren power plant location. The installation takes place in an empty machine hall and in module series to ensure flexibility for adaptation to future needs.

ArcelorMittal Bremen is a modern integrated metallurgical plant; all plants from pig iron production to thin sheet processing are united on the site.