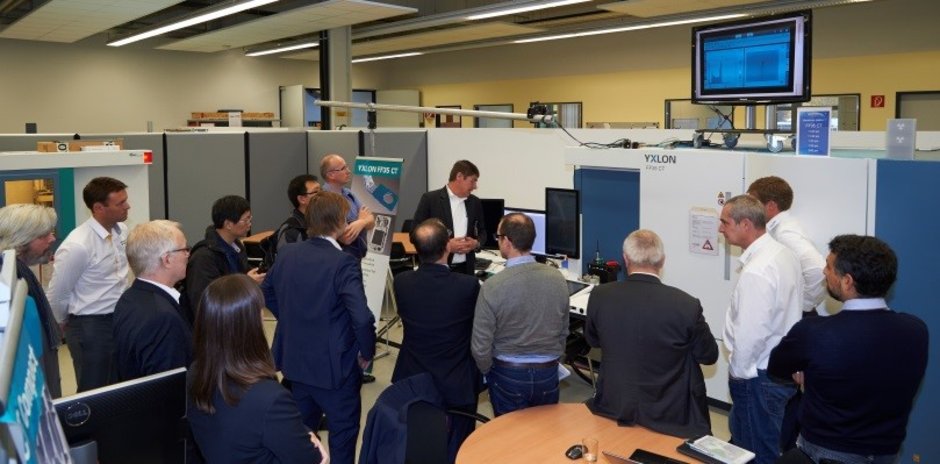

During a diversified schedule over two days, the topic “What has CT to do with Industry 4.0?” was considered at the YXLON CT User Conference 2016 in alternating presentations, hands-on sessions and panel discussions from different perspectives. Guest speakers from Airbus D&S France, the Hong Kong Polytechnic University, Laser Zentrum Nord (Germany) and Renault Formula OneTM Team (UK) delivered interesting insights into their various applications and experience with CT technology to the audience.

At first sight it seems difficult to see the connection between Computed Tomography and Industry 4.0 and the technologies behind them. “It is getting clearer, if one looks at the “fuel” which runs Industry 4.0: information”, Dr. Thomas Wenzel explains. “The combination of information in large bandwidth in excellent quality and the ability to exchange this information between production systems describes the necessities in order to reach the goals defined for Industry 4.0: increased product quality, cost and time efficiency, but also resource efficiency, flexibility, versatility and robustness.”

Computed tomography as a non-destructive inspection method offers a data density and information quality which can contribute a tremendous value to Industry 4.0. For this paradigm the quality of an individual specimen is not so important in the first place, but the trends in production, especially in serial inspection are. CT is able to provide a detail level of information which is superior to all other NDT methods. With this, the value for the user can be increased considerably: coming from a pure good/bad decision of an individual specimen and going to an integrated serial inspection for the control of up- and downstream production steps.

But thinking Industry 4.0 could do without human beings and transferring all production and inspection activities to intelligent machines whose decisions are only based on algorithms means a clear underestimate of the complexity of the processes. Keith Bryant from SMT Solutions captured it in a nutshell both in his presentation and during the panel discussion: “Industry 4.0 has huge advantages for the electronics manufacturing sector, however we still need the human interface within inspection, as some faults have several potential causes and a skilled technician is best able to interpret this. However accurate and ‘real time’ data and images will give them the detail needed for resolving these issues quickly and correctly.”

On the whole, both the guests and the hosts rated the CT User Conference a successful event. Although the expectations had been different due to different fields of activities and experience with computed tomography, all the participants confirmed that they would take home a lot of interesting information. “It’s a new approach to consider CT technology not only to be a non-destructive, 3-dimensional inspection method, but using the wealth of data within the framework of Industry 4.0 for example for process control in production. This will raise X-ray technology to a complete new level”, explained Bartosz Gapinski from Poznan University of Technology. He and his colleague Karol Grochalski were sure that the YXLON CT User Conference should be continued to take place annually and that they will be present again next year.

Source: YXLON

Partner

Foundry Daily News

CT & Industry 4.0: User Conference at YXLON highlights new opportunities

Lesedauer: min

[2]