At CastExpo 2013, Foseco will be illustrating the ways that can help create the greatest possible value for your foundry. Foseco will display feature example castings, refractories, riser sleeves and an actual INITEK convertor ladle, as well as a number of pieces of equipment. Foseco will have information on the features and application of the following products:

- ENERTEK* and KING-CARB* Crucibles

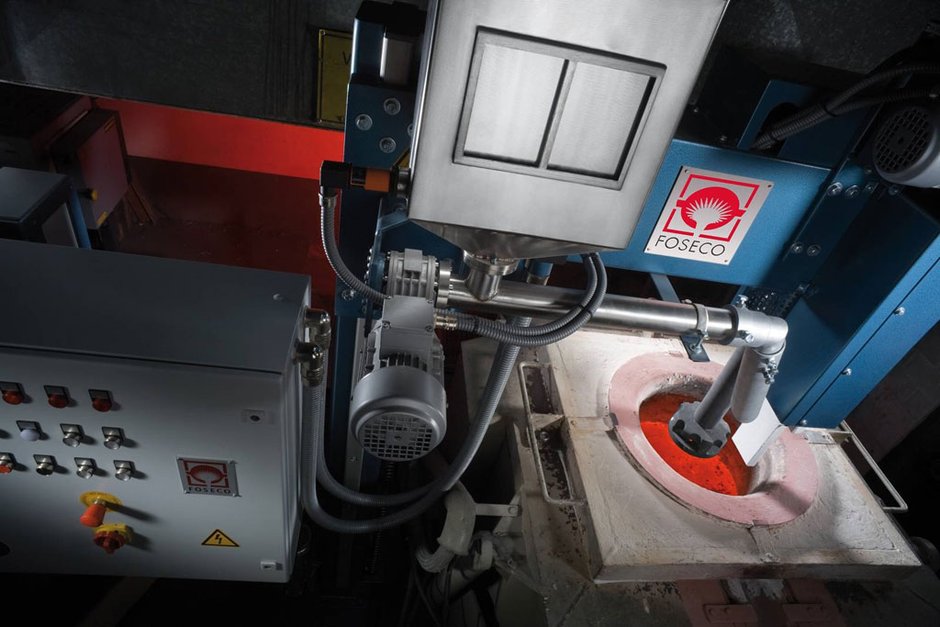

- MTS 1500 and ALSPEK* H Mini Non Ferrous Metal Treatment Systems

- DYCOTE* Non Ferrous Die Coatings

- HOLCOTE* and ISOMOL* Z-Primer refractory coating systems

- KALMINEX* K feeding systems for vertically parted green sand systems

- FEEDEX* K and KALMINEX* K dynamic riser systems

- Steel Foundry feeding systems

- STELEX* filters for steel castings

- KALTEK* ductile iron treatment ladle lining systems

- HOLLOTEX* filtration and flow control systems for large castings

- HOLLOTEX* EG – the new generation of gating systems

- INITEK* process

- Advanced Refractories

- Refractory Gunning Systems

- SERT UCERAM automated pouring systems for iron foundries

- SERT INOFEED-INOCHECK dynamic inoculation systems for iron foundries

Foseco is a leading manufacturer and provider of proprietary consumable products and solutions to the global foundry industry. Foseco are dedicated to helping customers improve their operations and businesses with innovative products and services, developing and commercializing the best ideas from customers, employees and our research labs to help customers reach the highest level of performance.

As part of Vesuvius PLC, Foseco's offering includes advanced melt deck, flow control and refractory products for melting and metal transfer applications in the foundry, along with binders, coatings, molding materials, crucibles, feeding systems, foundry filters, and metal treatment products. Foseco are committed to continuous improvement and total quality as a way of doing business U.S.-based product development facilities include computer simulation, water modeling, pilot plant capabilities, flow and dip coating facilities, high temperature thermo-physical and mechanical testing of refractories. Additionally an Analytical Services department operates a full complement of the latest testing equipment to support existing business segments and investigate new applications.