New from HUNTER

<link http: www.youtube.com _blank external-link-new-window external link in new>![]() Watch the JetSlingerTM in action!

Watch the JetSlingerTM in action!

- Impact-assisted flask filling, adjustable for cope and drag

- Venturi action air amplification for sand mixture dispersion

- Perpendicular flask filling, superior to side blow fill, no shadow effect

- Improves mold production up to 300% on selected jobs

- Better pattern definition, uniformity of mold hardness and surface finish

Available in late 2012 as optional equipment for Hunter XL2024 automated matchplate molding machines. Other XL models to follow shortly.

Retrofit your existing XL machines, too!

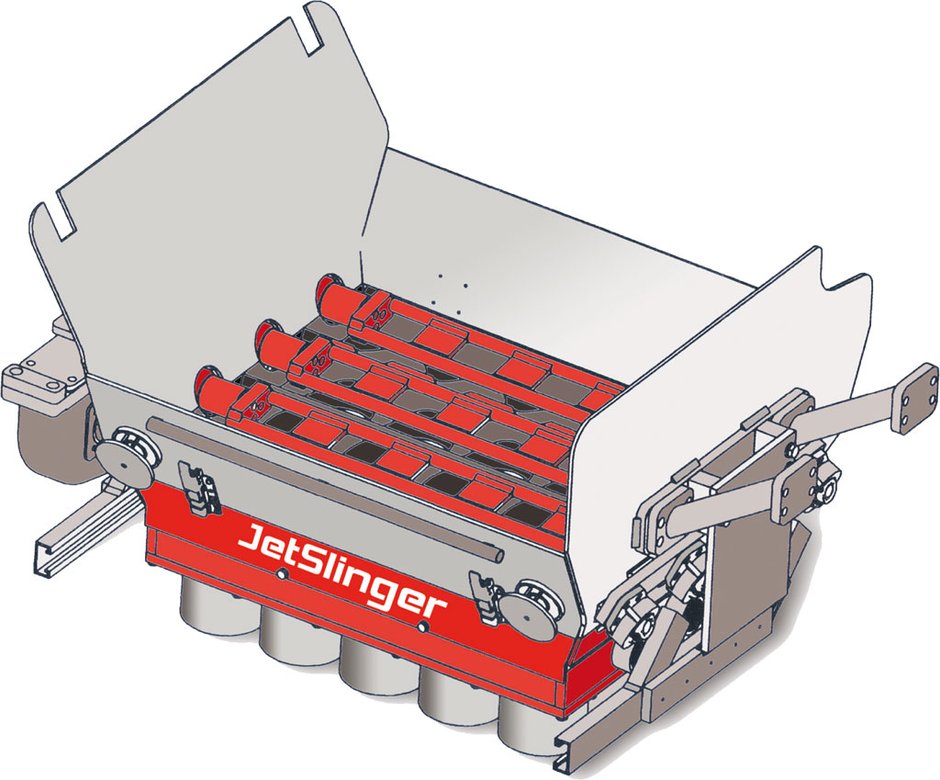

The Hunter JetSlingerTM device, an air amplification apparatus, based on the Venturi principle, accelerates the sand into the cope and drag flasks on the Hunter XL machines. Currently in Beta testing, this device creates a powerful vacuum and jet exhaust drawing the sand mixture through an array of nozzle assemblies built into a manifold mounted directly below the Fillaerator blades and then slinging the sand into the flask.

With a perpendicular fill, this impact-assisted device produces molds more quickly and with substantially improved surface quality, owing to the powered pre-compaction of the sand. This action results in greater uniformity of mold density and wall hardness, without sacrificing the accessibility and flexibility of a gravity fill machine.

The JetSlingerTM achieves a flask filling operation that compensates for mold quality limitations often caused by the flowability of the sand and pattern configuration during the high-pressure squeeze cycle.

In contrast to the conventional blow fill machines, there is no shroud, seals or vented flask assemblies required, along with the attendant maintenance. Further, the JetSlingerTM allows far greater flexibility and access needed to produce various castings with the use of chaplets, ram-up cores and exothermic risers.

The basic operation of the JetSlingerTM is as follows:

1. Sand mixture loaded into hopper

2. Hopper gates open

3. Rotating Fillaerator blades aerate the mixture

4. Mixture is delivered into the Venturi action air acceleration manifold

5. Mixture under pressure dispersed (slung) through 20 nozzles into the flask

6. Flask fills with pre-compaction around pattern plate

The JetSlingerTM was invented by company president Bill Hunter and the U.S. Patent Number US7819168B2 has been issued.

For more details, please contact:

Hunter Automated Machinery Corporation

2222 Hammond Drive

Schaumburg, Illinois 60194-1094

USA

Phone: +1 847 397 5120

Email: sales@hunterauto.com

Web: www.hunterauto.com

Attention: Bill Hunter or Mike Hughes

Note to media…

For additional information or graphics, please contact:

Tim Daro

Bernard & Company

Palatine, Illinois

USA

Phone: +1 847 934 4500

tdaro@bernardandcompany.com

Ad/PR agency for Hunter

The NEW LOOK for Hunter XL automated matchplate molding