Trends and challenges

As nations around the world plan to reduce emissions and create greener, more sustainable transport solutions, the pressure is on for the automotive industry to do the same. One direct result of a desire to reduce emissions is the automotive industries’ focus on ‘lightweighting’ new vehicles. The goal is to reduce overall vehicle weight to improve fuel economy, range and emissions from the growing number of hybrid and electric vehicles on our roads.

To achieve a reduction in overall vehicle weight, engineers are increasingly adopting a range of materials and production techniques to create lighter components for powertrains, drivetrains, and structural systems. This use of new materials - which include aluminium, carbon-fibre composites, high-strength steel, magnesium, and titanium - bring with them a need to re-think traditional manufacturing and assembly processes and embrace new technologies and techniques.

For die casting in particular, engineers must consider how to deliver improved quality and productivity for large and complex parts. Alongside this, production costs need to fall, the total cost of ownership needs to reduce, and the environmental impact of the die casting process must be lowered.

A shift towards larger die cast parts

The automotive industry is no stranger to automation, with many production lines already embracing Industry 4.0. Physical and digital processes have become increasingly intertwined in a bid to create smarter, more efficient production lines. Yet, with the pressure on to combine production efficiency with the use of lighter materials, there is change afoot.

Die casting has long been a key manufacturing process for the automotive industry. Traditionally used to cast parts such as engine blocks and transmission cases, the technique is now being used to cast one-piece structural parts such as shock towers and torque bars, aiding the ultimate goals of weight reduction. California-based electric vehicle manufacturer, Tesla, has recently announced a shift in production methods that favours the use of a single piece die cast underbody structure to replace a combination of multiple welded and stamped components. This requires use of the world’s largest die casting machine able to produce such a large one-piece casting - a change that could revolutionize the automotive industry.

Die casting: Weighing up the benefits

The benefits of die casting in the automotive industry are well known. A quick and relatively economical process, die casting offers the repeatability required by mass production, allowing identical parts to be produced using one mold.

The move towards engineering a vehicle structure from a smaller number of large die cast parts rather than high volumes of smaller parts reduces production complexity and offers significantly reduced costs. Casting larger parts stands to remove as many as 70 steps from a more traditional production process. While the benefits are clear to see, the casting of larger parts brings complexity to the die casting process. This is where innovative lubricants that are paired with the right equipment is required.

Water free lubricants: A sustainable solution for large and complex cast parts

To avoid compromising quality and increasing costs in the manufacture of large, complex components, specifying the correct die lubricant technology is essential to ensure an adequate release lubricant film is formed over the die surface.

As die tools increase in size and complexity, they become increasing difficult to lubricate using conventional water based lubricant systems. Ensuring lubricant reaches all parts of the complex tool to prevent casting failure is a significant challenge not easily overcome.

Lack of penetration of the lubricant spray into areas such as ribs, coupled with the low film forming capabilities of water-based lubricants is a real challenge faced by die casters. Additionally, the spray heads used to apply water-based lubricants are simply too large, bulky and inflexible to deploy lubricant to all areas of the die face successfully.

For an industry looking to cast larger components and also meet the challenges of maintaining product quality, improving productivity and reducing costs, water-free electrostatic lubricant systems, like Lubrolene® from Quaker Houghton, provide the best solution. Such systems combine a high-power release agent, free from the drawback of conventional lubricants, coupled with a compact low weight spray system.

When Lubrolene® WFR-EC is applied through a unique electrostatic spray gun, the lubricant spray droplets carry an electrostatic charge which, when coupled with a grounded die leads to unsurpassed lubricant deposition in all areas of the die. This includes deep ribs and other recessed features, which are very difficult to reach with other die lubricant technologies. The low weight and small footprint of the spray head coupled with the control features of the application system mean that lubricant application can be readily adjusted across the die face to give an optimized lubricating film.

As the lubricant product is also water free, any Leidenfrost effect, which is a significant problem with water based lubricants, is all but eliminated leading to unmatched lubricant deposition and adhesion on the die surface. The very high adhesion performance offered by electrostatic spray reduces the amount of release agents required by up to 99.9% per cycle.

As well as reducing ongoing running costs, the volumes of lubricant is significantly lowered, which combined with wax free lubricant formulations result in much reduced build-up on equipment. In turn, the need for cleaning of both spray head nozzles and dies is significantly lowered.

Added to the reliability, repeatability and preciseness of the system, the inherently lighter Lubrolene electrostatic spray head offers the only practical solution for producing ever larger structural parts in high pressure die casting machines that can range from 4,000 to 6,500 tonnes.

Once the practicalities of complex, one-piece die casting are resolved through the implementation of new technologies and solutions, the benefits for automotive manufacturers begin to emerge fully.

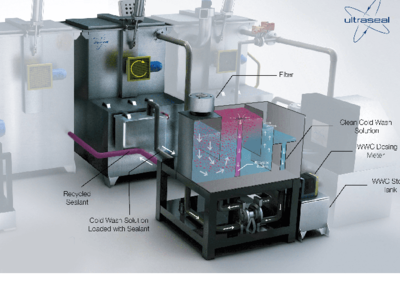

Reduced spray time, increased die life and a low reject rate all lead to enhanced benefits and cost savings for manufacturers. Combine that with zero wastewater from the process and reduced

CO₂ emissions (as a result of reduced air blow), and the environmental impacts of utilizing an efficient die casting release lubricant cannot be ignored.

Electrostatic spray: Increasing large die casting tool life by up to six times

Along with quality, tool service life is a significant issue in die casting. This is particularly the case with water-based agents, which rapidly cool the die surface between shots, leading to extreme temperature fluctuations of the die tool. These fluctuations can quickly lead to the formation of cracks on the die surface, as a result of repeated compressive and tensile stresses.

Cracks can typically start forming after several hundred shots and limits the tool’s service life before it needs to be repaired. This issue can be eliminated almost entirely by adopting water free electrostatic lubricant technology.

As Lubrolene is water free, the rapid cooling effect on the dies is eliminated, as is the thermal and stress cycle normally experienced with conventional water-based die lubricants, dramatically reducing crack formation. Effectively, this means Lubrolene WFR-EC can greatly extend tool service life and contribute to cost savings of more than €500,000 per annum. With extended tool service life, there are also less costs in servicing and maintenance, which then delivers further savings by up to 20 per cent, while process uptime is increased, and cycle time is decreased.

The future of die casting

For any industry that relies on metalworking, die casting has always been a popular choice. It owes its widespread use to the fact that it is versatile, reliable, accurate, and repeatable. However, as the automotive industry evolves towards using larger and more complex die cast parts, the latest die lubrication technology and equipment must be used. Only by doing so can processes be improved, the likelihood of porosity be reduced, overall costs and efficiency be maximized, and the impact on the planet lowered.

Switching from traditional water-based lubricants to a water-free electrostatic solution allows users to cast larger components with higher process temperatures, while also meeting the challenges of maintaining product quality, improving productivity, and reducing costs.

As a leader in industrial process fluids, Quaker Houghton offers a consultative approach to finding solutions that will optimize die casting processes, reduce costs, advance safety and drive sustainability. By embracing the latest technologies, die casters can meet current requirements to reduce the impact of their products and processes on the planet - at the same time as adding profit to their bottom line.

Find out more at ![]() https://iCasting.quakerhoughton.com.

https://iCasting.quakerhoughton.com.