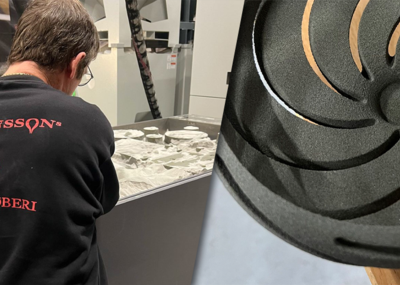

It is a rising star in AM with the speed and accuracy for high volume production breakthroughs. Sand binder jetting is helping foundries scale 3D printed core and mold production and deliver fast turnarounds without tooling lead times, rapid design changes, and exceptional design freedom to consolidate assemblies and create unique geometries.

3D printing super-user, Nattinee Valun-araya, Head of Engineering at Speed 3D Mold will provide insights on the day-to-day operation of an S-Max Furan binder jetting system. Speed 3D Mold supports a variety of applications with the technology and Mrs. Valun-araya will provide a deep dive into some of projects, including the use of helical sprues only possible with 3D printing and how they can provide fast replacement castings for legacy parts without tooling. Together with Mr. Ben Leung, Regional Vice President Asia of ExOne in APAC, she will also provide an outlook on the latest trends in the regional development of this disruptive technology.

Join ExOne for the webinar “Sand Binder Jetting - How Does it Work? Value Chain, Process & Applications” taking place on July 26th 3pm HKT.

Attendees will learn all about this AM process, from the CAT File all the way through the casting process. You will be able to get insights into different binder types and applications and the sand adoption process as well as an answer to the question print or pour.

Register for free here: Webinar-Registrierung - Zoom